-4849.jpg)

-4850.jpg)

-109-z-potaynou-holovkou-ta-kvadratnym-pidholovnykom-4629.jpg)

-129-z-potaynou-holovkou-ta-kvadratnym-pidholovnykom-4634.jpg)

-88-z-potaynou-holovkou-ta-kvadratnym-pidholovnykom-4631.jpg)

-129-s-potaynoy-holovkou-ta-dvoma-uporamy-4711.jpg)

-109-z-potaynou-holovkou-ta-dvoma-uporamy-4712.jpg)

-88-z-potaynou-holovkou-ta-dvoma-uporamy-4713.jpg)

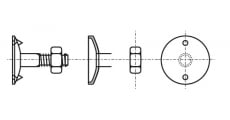

DIN 15237 Bolt elevator

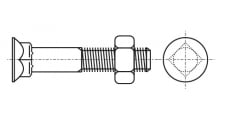

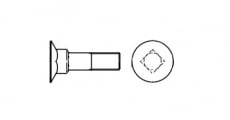

DIN 15237 Bolt elevator DIN 608 Countersunk head Bolt

DIN 608 Countersunk head Bolt-2280.jpg) DIN 604 Countersunk head bolt and mustache

DIN 604 Countersunk head bolt and mustache AN 263 countersunk head Bolt

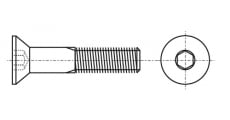

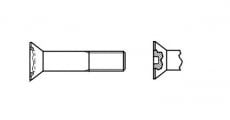

AN 263 countersunk head Bolt DIN 7991 Bolt with countersunk head for torx

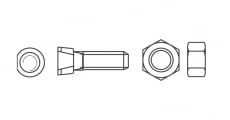

DIN 7991 Bolt with countersunk head for torx DIN 605 countersunk head Bolt and nut

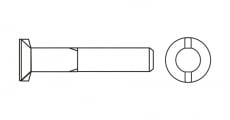

DIN 605 countersunk head Bolt and nut DIN 7969 countersunk head Bolt and straight slot

DIN 7969 countersunk head Bolt and straight slot DIN 11014 countersunk head Bolt with two stops

DIN 11014 countersunk head Bolt with two stops Special Bolt 1199-C with one conical cut

Special Bolt 1199-C with one conical cut-z-potaynou-holovkou-ta-kvadratnym-pidholovnykom-4685.jpg) Special Bolt 1199-A (DIN 608) with countersunk head and square headrest

Special Bolt 1199-A (DIN 608) with countersunk head and square headrest-z-potaynou-holovkou-ta-dvoma-uporamy-6916.jpg) Special Bolt 1199-B (ISO 5713, DIN 11014) with countersunk head and two stops

Special Bolt 1199-B (ISO 5713, DIN 11014) with countersunk head and two stops Special Bolt 1199-D with two conical cuts

Special Bolt 1199-D with two conical cuts Special Bolt 1199-O with concealed oval head and square headrest

Special Bolt 1199-O with concealed oval head and square headrest Special Bolt 1199-E with two conical cuts

Special Bolt 1199-E with two conical cuts

-4849.jpg)

-4850.jpg)

-109-z-potaynou-holovkou-ta-kvadratnym-pidholovnykom-4629.jpg)

-129-z-potaynou-holovkou-ta-kvadratnym-pidholovnykom-4634.jpg)

-88-z-potaynou-holovkou-ta-kvadratnym-pidholovnykom-4631.jpg)

-129-s-potaynoy-holovkou-ta-dvoma-uporamy-4711.jpg)

-109-z-potaynou-holovkou-ta-dvoma-uporamy-4712.jpg)

-88-z-potaynou-holovkou-ta-dvoma-uporamy-4713.jpg)

A countersunk head bolt is a fastener that is widely used in various industries, from construction to furniture manufacturing. The main purpose of using such bolts is to ensure that the fasteners are invisible and maintain a flat surface.

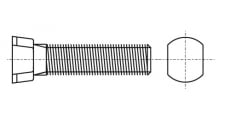

The design of a countersunk head bolt includes a flat head and a threaded rod. On the cap there is a slot in the form of a hexagonal hole, rectangle, star or cross, depending on the shape of the slot, the appropriate type of fastening tool is used for fastening work, it can be a screwdriver or wrench.

Countersunk head bolts are made from a variety of materials, including stainless steel, carbon steel, brass, or aluminum. This variety of materials allows you to choose the best option depending on the specific application.

The main feature of countersunk head bolts is that their head can be "sunk" into the material from which the parts are made. This helps to maintain a flat surface, hide the bolt heads, and provide an attractive appearance.

Countersunk head bolts are an integral part of building structures, providing reliable fastening and aesthetic appearance. Here are some of the main aspects of their use in construction:

- Fastening of metal structures

Pan head bolts are often used to connect metal structures in construction projects. They allow for a secure connection between steel beams, columns and other structural elements.

- Installation of cladding materials

In the interior and exterior cladding of buildings, countersunk head bolts are used to fasten a variety of materials, such as metal reinforcing mesh, aluminum panels, plastic composites, etc.

- Installation of wooden structures

In the construction of wooden buildings and structures, countersunk head bolts are used to fasten wooden beams, boards, and other elements. They create a strong connection, ensuring the structure's resistance to loads and environmental influences.

- Installation of facade systems

In modern construction, countersunk head bolts are widely used for the installation of facade systems, such as ventilated facades. They allow fixing facade panels without visible fasteners, which improves the appearance of the building.

- Installation of furniture and interior solutions

In the field of furniture production and interior design, countersunk head bolts are used to fasten furniture elements, decorative panels, and other parts. They allow you to create a modern and aesthetic design by hiding visible fasteners.

The use of countersunk head bolts in construction allows for strong and aesthetically pleasing structures, ensuring reliable fastening and durability of construction projects.

Countersunk head bolts have a number of advantages that make them popular in construction and other industries. Firstly, they provide reliable fastening, which is important for the safety and stability of building structures. Secondly, their aesthetic appearance allows you to hide the fasteners and create an attractive appearance of the building or furniture. In addition, countersunk head bolts provide a flat surface for the structure, which is important for achieving a perfect finish and smooth texture. They can be used in a variety of materials, including metal, wood, plastic, etc., which expands their application. All in all, countersunk head bolts are reliable, aesthetic and versatile fasteners that are widely used in construction and manufacturing.

Dinmark offers a wide range of countersunk head bolts that meet the highest standards of quality and reliability. Here are some of the advantages of Dinmark products:

1️⃣ A wide range of fasteners is available in one place, making us the best choice in Ukraine.

2️⃣ Save more: the more you buy, the lower the price for the product.

3️⃣ Additional 2% discount on all products when you buy on our website.

4️⃣ Fast delivery of goods both from the warehouse and under the order, so that you receive your purchases as soon as possible.

5️⃣ Our team of experts is always ready to help you choose the best hardware for your project.

So, by cooperating with Dinmark, you will experience even more benefits, as we strive to provide our customers with the highest quality products, a wide range of products, an individual approach to each client, fast delivery and professional advice on all issues related to fasteners and their use.

The price of countersunk head bolts may vary depending on the size, material, and manufacturer. However, it is important to remember that high quality and reliability of products are often key factors in the selection, as this guarantees the safety and durability of the structure.

When choosing a countersunk head bolt in the Dinmark online store, it is important to first determine the desired characteristics, such as size, head type, material, and other features. On the store's website, you will find detailed descriptions of each type of countersunk head bolt to help you make the right choice. You should also pay attention to customer reviews and product ratings to get additional information about the quality and satisfaction of other customers. If you have any additional questions or need advice, you can always contact the store's consultants, who will be happy to help you make the right choice.

Dinmark provides a quality guarantee for all of its products, including countersunk head bolts. The duration of the warranty may vary depending on the specific product and the terms of sale. In general, the warranty for countersunk head bolts is usually valid for 12 months from the date of purchase. This means that during this period, you can contact the store in case of any problems with the product and you will be provided with the necessary support, including replacement or return of the product, provided that you comply with the established terms and conditions of the warranty.

Standards and regulations play an important role in the production and use of countersunk bolts. Two of the most well-known standards in this area are ISO 10642 and GOST 7785-81 ("Bolts with countersunk head and whisker of accuracy class C").

ISO 10642 sets out the requirements for the dimensions and features of countersunk head bolts. This standard also defines the technical characteristics that ensure high quality and reliability of fasteners.

GOST 7785-81 sets out the requirements for countersunk head bolts and includes recommendations for the production, testing and use of these fasteners. This standard helps to ensure that countersunk head bolts meet all the necessary safety and reliability requirements.

Compliance with the requirements of these standards helps to ensure the high quality and reliability of countersunk head bolts, as well as to prove their compliance with the requirements of customers and regulatory authorities.

To summarize, countersunk head bolts are an important element in construction and manufacturing, and their design and properties allow for reliable and aesthetic fastening. Compliance with the requirements of standards and regulations guarantees high quality and safe use of these products.

Enter your email address to follow the Dinmark news