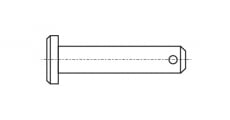

DIN 1444-B Low head pin with hole

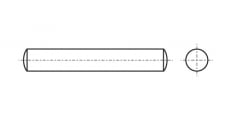

DIN 1444-B Low head pin with hole DIN 6325 Pin cylindrical hardened

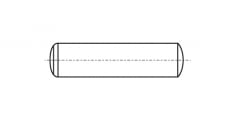

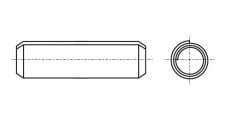

DIN 6325 Pin cylindrical hardened DIN 7 Cylindrical pin

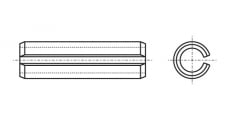

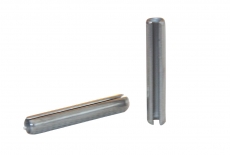

DIN 7 Cylindrical pin DIN 1481 Cylindrical spring pin

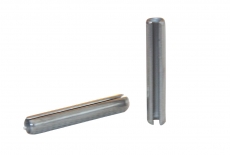

DIN 1481 Cylindrical spring pin DIN 7343 Cylindrical spring pin

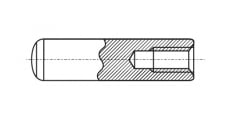

DIN 7343 Cylindrical spring pin DIN 7979 Cylindrical pin with female thread

DIN 7979 Cylindrical pin with female thread DIN 1473 Pin cylindrical with notch

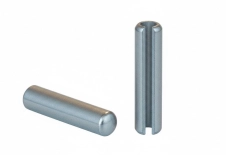

DIN 1473 Pin cylindrical with notch DIN 7346 Cylindrical spring pin with slot

DIN 7346 Cylindrical spring pin with slot DIN 1476 Cylindrical pin with semicircular head

DIN 1476 Cylindrical pin with semicircular head DIN 7344 Cylindrical spring pin

DIN 7344 Cylindrical spring pin DIN 1434 B Cylindrical pin

DIN 1434 B Cylindrical pin DIN 1475 Cylindrical pin with central notch

DIN 1475 Cylindrical pin with central notch DIN 1474 Cylindrical driving pin with notch

DIN 1474 Cylindrical driving pin with notch  DIN 1477 Cylindrical pin with countersunk head and notch

DIN 1477 Cylindrical pin with countersunk head and notch ART 8558 Pin with rounded head

ART 8558 Pin with rounded head AN 124 Pin with spring protection

AN 124 Pin with spring protection

Cylindrical pins are smooth or springy cylindrical metal rods used to fix, center or connect parts in mechanisms. They do not have a thread, they are fastened due to a tight fit in the corresponding hole. This type of fastening guarantees high accuracy and stability of the position of the elements.

The products are smooth, with chamfers, with holes or elastic (spring). The material for production is carbon or stainless steel, sometimes with a coating to protect against corrosion.

Dimensions are determined by diameter and length. The diameter varies from 1 mm to 25 mm. Length — from 4 mm to more than 100 mm. The choice of parameters depends on the design features of the parts and operating conditions.

The correct selection ensures a tight fit without backlash. For elastic pins, the degree of compression is taken into account - this affects the fixation. Price depends on size, standard and material.

Production begins with the cutting of steel blanks. Next, turning is performed with diameter accuracy control. For spring pins, rolling or forming a spiral is performed. In the final stage — heat treatment and grinding.

Each product is checked for accuracy of fit, hardness and compliance with standards. The result is a precise and durable fastener.

These pins are used in machine tools, gearboxes, couplings, gears, equipment housings. They provide reliable centering, prevent rotation and displacement of parts.

They are also used in the assembly of devices, equipment, and medical equipment. Their precision and simplicity make them popular in any branch of mechanical engineering.

1️⃣ Huge selection of fasteners: A unique opportunity to find all necessary fasteners in one place - the largest assortment in Ukraine.

2️⃣ Flexible pricing policy: The more you buy, the lower the price you will get, providing favorable conditions for large orders.

3️⃣ Additional discount: When making a purchase on the website, you automatically receive an additional -2% discount on the entire range.

4️⃣ Fast delivery: Enjoy fast delivery of goods both from the warehouse and to order, ensuring the speed and convenience of receiving purchases.

5️⃣ Expert support: Our team of experts is always ready to help you choose the right mount, guaranteeing professional advice and support.

Dinmark has a wide selection of items including:

DIN 1444-B — with a hole for a cotter pin

DIN 1481 — elastic pins (spiral)

DIN 6325 — with a chamfer for exact centering

DIN 7 — classic smooth pins

Each standard takes into account the specifics of application, fit and strength. Cylindrical DIN pins meet international standards and are widely used in industry.

The best ones are those that exactly match the working conditions. Flexible DIN 1481 are suitable for repeated installation. For precise connection - polished DIN 7. In difficult conditions - heat-treated DIN 6325.

Cylindrical pins are selected according to several key parameters. First of all this diameter and length—these must match the hole exactly to ensure a tight fit without play or damage. Next, pay attention to the material: carbon steel - for standard conditions, stainless - for wet or aggressive environments, brass - for light structures. It is also importanthide a manufacturing standard (such as DIN or ISO) that guarantees dimensional accuracy and interchangeability. And finally, look at the installation conditions: for permanent connection — pins without additional elements.

In 2025, DIN 1481 will remain popular — flexible, wear-resistant, conveniently mounted. DIN 6325 is also recommended for responsible fastening in production. They combine accuracy, reliability and ease of installation, so you should determine your needs and buy Cylindrical pins.

Enter your email address to follow the Dinmark news