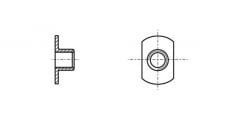

DIN 929 Welded nut

DIN 929 Welded nut DIN 928 Square welded nut

DIN 928 Square welded nut Pressed nut

Pressed nut ART 9064 Nut pressed

ART 9064 Nut pressed ART 9060 Welded nut

ART 9060 Welded nut

Welded nuts are special fasteners used to create strong and durable connections in various metal structures. The main feature of these nuts is that they can be welded to a metal surface, which ensures high reliability of fixation and no need for additional retaining parts. They have special protrusions or corrugations to facilitate the welding process and prevent material deformation.

Due to the variety of shapes and designs, welded nuts are used in automotive manufacturing, construction, engineering and other industries. Their main advantages are resistance to vibrations, the ability to work under high loads, and durability.

The main types of weld nuts include:

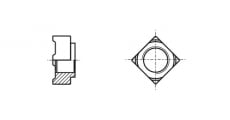

Square welded nuts (DIN 928) - have a quadrangular shape and distribute the load evenly over the connection plane.

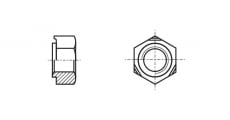

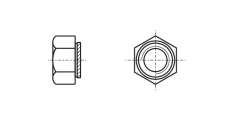

Hexagonal welded nuts (DIN 929) - provide ease of installation and securely hold the connection.

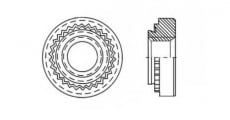

Round welded nuts - used in situations where uniform load transfer is important.

Pressed-in nut - a special type of nut used in thin-walled metal products to ensure a strong threaded connection.

The Dinmark online store offers a wide range of weld nuts that meet the most common international standards, in particular

DIN 929 - hexagonal welded nuts, which are ideal for industrial and building structures.

DIN 928 - square welded nuts, which are often used in mechanical engineering and metal structures.

The manufacturing process of welded nuts includes several key stages, each of which is critical to ensuring their quality and durability. It all starts with the choice of material. Carbon or stainless steel is most commonly used, which provides high strength and corrosion resistance. Next comes the process of forming the blanks, which can be done by stamping or casting, depending on the specific type of nut.

This is followed by cutting the internal thread, which is performed with high precision to ensure a secure connection to the bolt or stud. After machining, the nuts are subjected to additional heat or chemical treatment to increase their wear resistance and durability. The final stage is the application of a protective coating, such as galvanizing or phosphating, which helps prevent corrosion and provides additional protection in harsh environments.

Welded nuts are widely used in many industries due to their technical characteristics and reliability. In the automotive industry, they are an integral part of the body structure, where they provide reliable fastening of metal parts. They are also widely used in mechanical engineering, where they are used to connect various elements of machinery and equipment, guaranteeing high strength and durability.

In the construction industry, welded nuts are used to fix load-bearing metal structures, ensuring a reliable connection even under heavy loads. In addition, they are used in the production of ventilation systems, electrical switchboard equipment and other technological industries where fixing elements on metal surfaces is required. We should also note the popularity of welded square nuts, which guarantee resistance to mechanical stress and long service life.

1️⃣ Huge selection of fasteners: A unique opportunity to find all the necessary fasteners in one place - the largest assortment in Ukraine.

2️⃣ Flexible pricing policy: The more you buy, the lower the price you get, providing favorable conditions for large orders.

3️⃣ Additional discount: When you make a purchase on the site, you automatically get an additional -2% discount on the entire range.

4️⃣ Fast delivery: Enjoy fast delivery of goods both from the warehouse and under the order, providing speed and convenience of receiving purchases.

5️⃣ Expert support: Our team of experts is always ready to help you choose the right fastener, guaranteeing professional advice and support.

Experience even more benefits by cooperating with DINMARK - your reliable partner in the fastener industry! Here you can always buy Welded nuts in assortment.

For industrial and building structures, the best choice is a welded square nut, which provides high reliability of the connection.

You can familiarize yourself with the assortment and select the necessary fasteners on the Dinmark website. Our managers are also ready to provide advice on choosing the right nuts for your project.

In 2025, DIN 928 and DIN 929 will be in the greatest demand as they guarantee durability and reliability.

Don't miss out - you can buy weld nuts today! At Dinmark, you will find the best fasteners at a competitive price.

Enter your email address to follow the Dinmark news