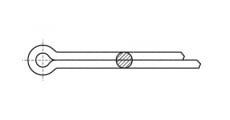

DIN 94 Adjustable cotter pin

DIN 94 Adjustable cotter pin

Cotter pins are simple metal products that are used to fix nuts, keys, fingers or other elements. They do not have a thread, and their reliability is achieved due to the thinning of the antennae after installation. Most often, they are used as an additional lock in machinery, cars, and agricultural machinery.

A classic splint has the shape of a bent wire with an eye. One end is round, the other is straight. After insertion into the corresponding hole, the ends are spread to the sides, which prevents the part from coming out of the hole on its own. This is a simple but effective system of preventing loosening of fasteners.

Unlike screws or bolts, cotter pins do not create a clamping force, but perform a locking function. They are often combined with threaded elements. The most popular — DIN 94 cotter pin, available from Dinmark in various diameters. These products are easy to install and do not require special tools.

Cotter pins are classified by shape, size, type of material and manufacturing standard. The most common option — cotter pin according to the DIN 94 standard, made of steel wire. It has a straight leg with fork, which after installation is separated for fixation.

By form there are:

straight cotter pins — classic type for fastening in holes of shafts and nuts;

curved cotter pins — provide additional fixing effort;

cotter pins with a ring — convenient for dismantling.

According to the material, galvanized steel, stainless and brass models are used. Stainless pins are recommended for aggressive environments - sea water, moisture, chemicals. Brass - for electrical installation and devices where chemical neutrality is important.

Cotter pins are used as locking elements in structures where it is necessary to fix nuts, pulleys or shafts. The main task is to prevent spontaneous unscrewing of elements under load or vibrations.

Most often, splints are used:

in mechanical engineering — fixing pulleys, bushings, clutches;

in agricultural machinery — in axles, trailers, couplings;

in construction — in rigging systems and mobile units;

in equipment repair — when assembling mechanisms subject to load.

Ease of installation and the possibility of quick disassembly make cotter pins a convenient element for temporary or serviceable connections. It is important to choose the correct diameter and length according to the hole in the part to ensure reliable fixation.

Choose a cotter pin by the diameter of the hole into which it is inserted and by the length that allows you to safely separate the ends. The material is carbon or stainless steel. For conditions with high humidity, it is better to choose stainless models. That buy cotter pins pcorrectly, it is important to know the exact hole type, diameter and mechanical load.

1️⃣ Convenient fastening solution: the largest range of all types of fastening in Ukraine.

2️⃣ Savings with each order: the more purchases, the better the price for the product.

3️⃣ Bonuses for online purchases: an additional -2% discount on all products when ordering through the site.

4️⃣ Fast delivery: individual orders are also possible.

5️⃣ Professional support: a team of experts is ready to help you choose the necessary hardware quickly and efficiently.

Therefore, it is worth buying splints right here and get even more benefits from DINMARK!

The best ones are made of high-quality steel that does not break when bent. For the street - galvanized or stainless.

They are used in mechanical engineering, agriculture, aviation, shipbuilding and construction for fixing nodes.

In 2025 it is recommended to buy split pins DIN 94 are standard, proven models with a wide range of diameters and lengths.

Enter your email address to follow the Dinmark news