- 1

- 2

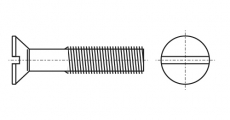

DIN 963 Screw with countersunk head and straight slot

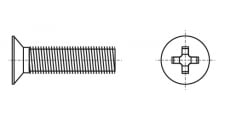

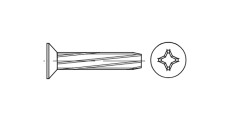

DIN 963 Screw with countersunk head and straight slot DIN 965 Countersunk head screw

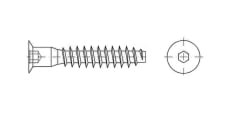

DIN 965 Countersunk head screw ART 3401 Screw confirmat with hidden head

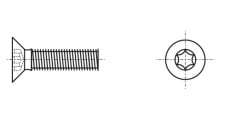

ART 3401 Screw confirmat with hidden head DIN 7500 M Self-tapping screw with countersunk head

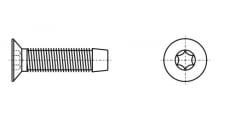

DIN 7500 M Self-tapping screw with countersunk head ISO 14581 Screw with countersunk head under torx

ISO 14581 Screw with countersunk head under torx DIN 7516 D self-tapping Screw with countersunk head

DIN 7516 D self-tapping Screw with countersunk head

Countersunk head screws are indispensable in many industries due to their ergonomic design, which allows them to fasten parts without protruding above the surface of the material. They are widely used in construction, furniture manufacturing, automotive, electronics, and other industries where it is important to maintain a flat surface or ensure the aesthetic appearance of structures. Countersunk screws avoid snagging, provide greater connection reliability, and add stability and durability to the structure.

The range of countersunk screws is extremely broad and includes DIN 963, DIN 965 and ISO 14581 standards, among others. DIN 963 countersunk screws have a straight slot, which allows them to be securely fixed in the material. DIN 965 screws are more versatile and have a cross slot, which provides a more secure fastening. ISO 14581 combines elements of the previous standards, adapting them for applications with increased requirements for precision and safety of fastening. The variety of standards makes it possible to choose the best option for any industry.

Countersunk head screws have certain technical requirements that determine their reliability and resistance to external loads. The main parameters to consider are thread diameter, length, strength class, and slot type. The diameter and length of the screw depend on the purpose of the fastener and the thickness of the material being worked with. Standard sizes usually range from M2 to M20. For the installation of countersunk screws with special strength requirements, the strength class parameter is also important, which usually ranges from 8.8 to 12.9.

The materials from which screws are made have a significant impact on their properties. The most common options include:

Steel is the most popular material because it provides strength and durability.

Stainless steel is the best choice for environments with high humidity or aggressive chemicals.

Brass and bronze - suitable for use in decorative or special designs where aesthetics and corrosion protection are important.

Titanium alloys are the best option for the aviation and medical industries due to their lightness and high corrosion resistance.

Knurled head screws are available in a variety of sizes to meet the requirements of different industries. The most popular diameters are M3, M4, M5 and M6 for small domestic and industrial constructions. For larger projects, M8, M10 and even larger diameters are used, depending on the loads that the screw must withstand. The length of the screws varies from a few millimeters to several centimeters, allowing you to choose the best option for each specific case.

1️⃣ A huge selection of fasteners: A unique opportunity to find all the necessary fasteners in one place - the largest assortment in Ukraine.

2️⃣ Flexible pricing policy: The more you buy, the lower the price you get, providing favorable conditions for large orders.

3️⃣ Additional discount: When you make a purchase on the site, you automatically get an additional -2% discount on the entire range.

4️⃣ Fast delivery: Enjoy fast delivery of goods both from the warehouse and under the order, providing speed and convenience of receiving purchases.

5️⃣ Expert support: Our team of experts is always ready to help you choose the right fastener, guaranteeing professional advice and support.

Experience even more benefits by working with DINMARK - your reliable partner in the fastener industry!

The choice of screws depends on the design features, the loads they must withstand, and the material. It is important to consider the size and strength class of the screw, as well as the material that meets the operating conditions. Dinmark provides detailed descriptions of the characteristics of each product, which simplifies the selection process.

Prices for countersunk screws depend on their material, size and strength class. The average price range ranges from 1 to 5 UAH per unit for small screws and up to 20 UAH per unit for larger and stronger options.

for larger and stronger options. You can buy countersunk screws from Dinmark, our online store offers discounts for large orders and constantly updates promotional offers, the price also varies according to the number of items in the order.

In 2025, the most popular screws are those of DIN 965 and ISO 14581 standards, which are used in both domestic and industrial projects due to their versatility and durability. Stainless steel screws are also popular, as they provide reliable protection against corrosion in high humidity conditions.

Countersunk screws remain an essential element for safe and aesthetic fastening in all types of construction. Thanks to the variety of standards, materials and sizes, it is easy to find the best option for your needs. Dinmark offers a wide range of products and is ready to provide you with high-quality screws for any application.

Enter your email address to follow the Dinmark news