DIN 1 Conical pin

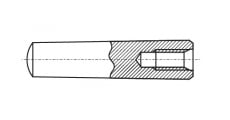

DIN 1 Conical pin DIN 7977 Conical pin with thread and pin

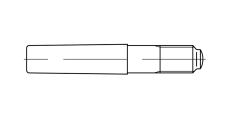

DIN 7977 Conical pin with thread and pin ISO 2339 Cone pin

ISO 2339 Cone pin DIN 7978 Taper pin with female thread

DIN 7978 Taper pin with female thread DIN 1471 Taper pin with notch

DIN 1471 Taper pin with notch DIN 1472 Taper pin with notch

DIN 1472 Taper pin with notch DIN 258 Conical pin with threaded pin

DIN 258 Conical pin with threaded pin

Conical pins are special metal cylindrical elements with a gradually narrowed diameter. They are used to fix parts relative to each other, ensuring accurate positioning without displacement. The main feature is the conical shape, which allows you to achieve self-braking during installation, without additional fastening elements.

A conical metal pin is usually made of carbon or alloy steel, sometimes of stainless alloys. The surface can be heat treated or phosphated to increase wear resistance. The taper is preferably 1:50, which ensures an even entry into the landing hole.

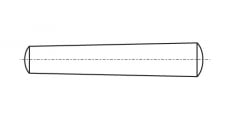

Cone pins are divided according to several characteristics: by the type of head: with a chamfer, with a head, without a head, by length: from 10 to 120 mm, by diameter: from 1 to 20 mm.

The dimensions are chosen according to the hole into which the pin is inserted. Tolerances are important, as too tight or too loose a joint reduces the effectiveness of the fastener. In addition, products can be with an internal thread for dismantling or without it - for permanent connections.

The price of a conical pin depends on the material, manufacturing accuracy and standard. On the Dinmark website, all the necessary information for the correct selection of the product is available.

Dinmark offers a wide range of products, including:

ISO 2339 — precise conical with a machined surface

DIN 1 — classic models for universal use

DIN 7977 — with a thread for easy disassembly

Each standard takes into account the features of fit, tolerances, strength. All models are made of high-quality steel with precise processing. Buy a conical pin in Dinmark means getting a certified product with a guarantee of accuracy.

The production of conical pins begins with the preparation of a metal blank. Next, turning is carried out to ensure the desired cone. An important stage is heat treatment, which adds strength and resistance to loads.

After that, grinding and geometry control is performed. In the case of threaded models, additional mechanical processing is carried out. Quality control guarantees the accuracy of the diameter, taper, as well as compliance with the parameters of the standard.

Cone pins are widely used in mechanical engineering, instrument engineering, metalworking, aircraft and automobile engineering. Their main task is to fix two elements in a strictly defined position without backlash.

They are often used in molds, tooling, parts with high precision of connection. Thanks to the conical shape, not only fixation is ensured, but also centering, which is important for rotating mechanisms and supporting elements.

1️⃣ Huge selection of fasteners: A unique opportunity to find all necessary fasteners in one place - the largest assortment in Ukraine.

2️⃣ Flexible pricing policy: The more you buy, the lower the price you will get, providing favorable conditions for large orders.

3️⃣ Additional discount: When making a purchase on the website, you automatically receive an additional -2% discount on the entire range.

4️⃣ Fast delivery: Enjoy fast delivery of goods both from the warehouse and to order, ensuring the speed and convenience of receiving purchases.

5️⃣ Expert support: Our team of experts is always ready to help you choose the right mount, guaranteeing professional advice and support.

Experience even more benefits by cooperating with DINMARK - your reliable partner in the field of fasteners!

The best are those made of heat-treated steel, with a precise taper angle and conforming to ISO or DIN standards. Depending on the task, you should choose a model with or without thread.

At Dinmark you will find a wide range of taper pins at competitive prices. Our pins comply with international standards such as ISO 2339, DIN 1 and DIN 7977, which ensures high quality and reliability of each product. The cost of pins depends on the material of manufacture, diameter, length and type of coating for increased wear resistance.

The first step is to determine the diameter of the pin in the narrow and wide part. This is a key parameter, because the pin is inserted into the tapered hole, and the correct matching of the diameters ensures self-clamping and a strong connection. If this nuance is not taken into account, the fixation will be unreliable, and the separation of parts will be unpredictable.

No less important is the length of the pin. It should correspond to the depth of the landing hole and the design of the node. A pin that is too short will not provide sufficient fixation, and a pin that is too long may protrude beyond the part, creating a risk of damage or making disassembly difficult.

The presence of a thread for dismantling should also be taken into account. In cases where the dismantling of elements is planned regularly or there is a need for maintenance, it is better to choose pins with a threaded hole or pins with a head - this makes extraction after use much easier.

Another critically important indicator is the taper angle. It must exactly match the hole in the receiving part. The standard angle is usually 1:50 or 1:20, but other values may be used for specific applications. Inaccurate angle matching leads to insufficient clamping effect or excessive load on the material.

The last but no less important parameter is the material and protective coating of the pin. For highly loaded mechanisms, it is recommended to use pins made of hardened steel, which can have a phosphated, galvanized or oxidized coating. This provides corrosion protection, reduces wear and extends service life.

In 2025, pins made of heat-treated steel with a phosphate coating are relevant. The DIN 7977 models with internal thread for disassembly are especially recommended. It is the optimal choice for responsible installations and industrial applications.

Enter your email address to follow the Dinmark news