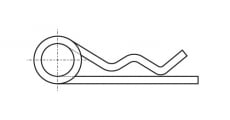

Spring cotter pins

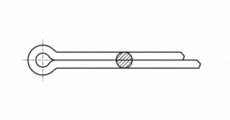

Spring cotter pins Split cotter pin

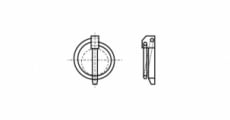

Split cotter pin Pins with a ring

Pins with a ring

Ring cotter pins are special fasteners used to connect or secure parts. They have the form of a loop or ring that prevents the splint from falling out after it is installed.

Ring cotter pins can be used in a variety of areas, including mechanical engineering, transportation, construction, and other industries. They are used to connect moving parts, hold rods, shafts, pulleys and other components that can rotate or move. Ring cotter pins are often used where it is necessary to ensure a reliable and safe connection, as well as an easy possibility of disassembly.

In general, ring cotter pins are important elements in many industries and are used for a variety of tasks where a reliable and safe connection of parts is required.

Spring cotter pins are a type of fasteners used to connect or secure parts and prevent them from falling out. They are in the form of a spring that can be inserted through a hole in a shaft or other part, creating a tensioned connection.

Spring cotter pins are often used in mechanical engineering, mechanical manufacturing, and engineering applications. They allow you to connect moving parts, such as shafts, rods, pulleys and others, ensuring reliable retention and connection during movement or loading.

The principle of operation is that the spring pin is inserted into the hole, then according to its design it opens and is fixed in the shaft or part. This creates a tight connection that ensures a secure hold.

Spring cotter pins are important components for some structures where it is important to avoid parts or elements falling out. Their use can simplify the process of connection and disassembly, while ensuring a high level of reliability.

Split cotter pins are fasteners used to fasten and connect parts, and to allow quick assembly or disassembly of these parts without the need for tools.

Split cotter pins have a specific design that allows them to fit into a shaft or hole and then lock in the open position, gripping the parts and holding them together. They are used in situations where it is necessary to frequently disconnect or disassemble parts, for example, for ease of maintenance or transportation.

Split cotter pins can be used in various industries, including mechanical engineering, transport, furniture manufacturing, construction and other fields. They help save time and effort that would be spent on using other fasteners during disassembly or assembly of parts.

In general, split pins are practical solutions for situations where it is necessary to combine a reliable connection with the possibility of quick and easy disconnection or assembly of parts.

The installation and use of cotter pins is a process in which a cotter pin (a spring-shaped fastener) is inserted into a hole in parts or shafts and locked in an open position to provide a secure connection. Choosing the right type and size of cotter pin, preparation of parts, insertion, fastening ensure an effective connection, reduce installation effort and provide convenience when disassembly is required.

The "Dinmark" website presents a wide range of cotter pins, which includes various types, sizes and configurations. You will be able to find cotter pins in different types and materials, such as steel or stainless, which can be used for different applications. Regardless of your needs, on the "Dinmark" website you will find various options of cotter pins that will satisfy different requirements and conditions of use.

Enter your email address to follow the Dinmark news