-5638.jpg)

- 1

- 2

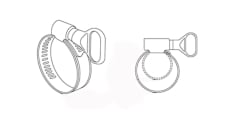

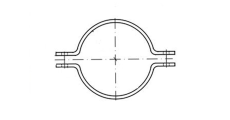

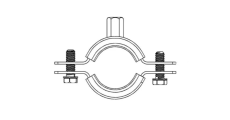

DIN 3016 Clamp with EPDM substrate

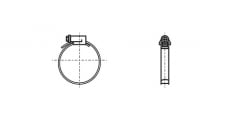

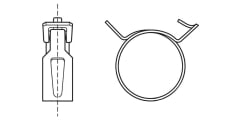

DIN 3016 Clamp with EPDM substrate DIN 3017-A Worm clamp

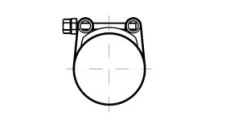

DIN 3017-A Worm clamp DIN 3017-C Power clamp

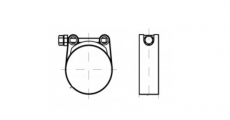

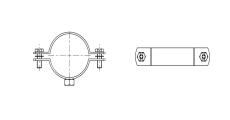

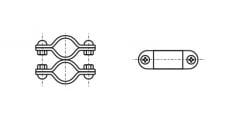

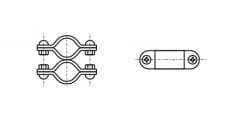

DIN 3017-C Power clamp DIN 3567 Pipe clamp

DIN 3567 Pipe clamp DIN 3570 U-shaped clamp

DIN 3570 U-shaped clamp DIN 3575 U-shaped clamp

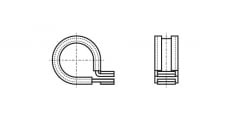

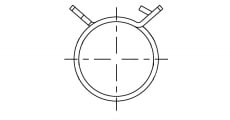

DIN 3575 U-shaped clamp ~ DIN 3021 Spring clamp

~ DIN 3021 Spring clamp ART 60 Pipe clamp with inch thread

ART 60 Pipe clamp with inch thread AN 64 Z Lock for clamp DIN 3017-A

AN 64 Z Lock for clamp DIN 3017-A ART 3017 Mini power clamp

ART 3017 Mini power clamp ART 3018 Spring clamp

ART 3018 Spring clamp ART 7354 Clamp

ART 7354 Clamp ART 7460 Clamp

ART 7460 Clamp ART 8461 Clamp

ART 8461 Clamp Clamp FLECAV clampCT-CLIP clampECLIP clampV ventilation clamp

Clamp FLECAV clampCT-CLIP clampECLIP clampV ventilation clamp

-5638.jpg)

Clamps are universal fasteners that are used to fix and connect pipes, hoses, cables and other cylindrical elements. The main function of the clamp is to tightly compress the object for the purpose of sealing or stable fastening. Most models consist of a metal or plastic band that closes around the element with a latch. The most common are worm clamps — they have a screw mechanism that allows you to adjust the tightening force. Such products are easily installed by hand and provide reliable fastening without deformation of the material.

Structurally, the clamp may include spacers to protect the insulation, an anti-corrosion coating, or additional fasteners for complex systems. Due to their simplicity, reliability and versatility, these mtyses have become indispensable in many technical fields.

The size of the clamps is determined by the inner diameter in the stretched state. Models available from 8mm to over 300mm. Standard diameters cover domestic and industrial needs. The width of the tape also varies. For small loads, narrow options of 8-12 mm are chosen, and for large pipes - models with a width of up to 25 mm. It is also important to consider the thickness of the material — it affects strength and wear resistance. For the correct choice, it is important to take into account the diameter of the object, the pressure force and the operating conditions. You can buy clamps in Dinmark with detailed characteristics, which simplifies the choice and ensures the accuracy of installation.

The production process of clamps begins with the selection of raw materials — mainly stainless steel or polyamide. After that, the metal goes through the stamping stage, where the tape and fixing elements are formed. Next, processing of edges, drilling of holes and coating is performed. Special attention is paid to the worm mechanism — the precision of the screw transmission guarantees uniform tightening. For plastic clamps, the correct molding temperature is important to avoid brittleness. The final stage is a check for strength, corrosion resistance and dimensional compliance.

These products are used in many areas: plumbing systems; automobile industry; electrical installation; ventilation and air conditioning. They are also used in the food, pharmaceutical and chemical industries due to their resistance to aggressive environments. Due to the simplicity of the design and versatility, these hardware are often used in everyday life - for repair, installation of pipes, cables and other elements.

1️⃣ Huge selection of fasteners: A unique opportunity to find all necessary fasteners in one place - the largest assortment in Ukraine.

2️⃣ Flexible pricing policy: The more you buy, the lower the price you will get, providing favorable conditions for large orders.

3️⃣ Additional discount: When making a purchase on the website, you automatically receive an additional -2% discount on the entire range.

4️⃣ Fast delivery: Enjoy fast delivery of goods both from the warehouse and to order, ensuring the speed and convenience of receiving purchases.

5️⃣ Expert support: Our team of experts is always ready to help you choose the right mount, guaranteeing professional advice and support.

Dinmark offers a wide range of clamps, including popular models:

FROM 317-A — universal spring products for light connections

FROM 3567 - two-bolt, for heavy pipes

DIN 3017 — classic, worm, power stainless steel

DIN 7354 — reinforced ribbons, with a wide grip

Each model is designed for specific application conditions — from water supply systems to the automotive industry.

The best ones are the ones that exactly match your technical requirements. If you need a strong fastening for pipes - choose DIN 3017. For mobile systems - spring DIN 317-A. In industrial projects, DIN 3567 has proven itself best.

The selection of clamps should be based exclusively on technical characteristics that meet the conditions of their future use. First of all, it is necessary to take into account the diameter of the pipe or hose - this parameter affects the tightness of the fit and the tightness of the connection. An incorrectly selected diameter can lead to leaks or premature wear of elements.

Next, you should determine the type of connection that is most suitable for a specific task. For example, worms ware ideal for permanent connections that do not need to be opened frequently, while spring-loaded connections are better able to cope with pressure or temperature fluctuations. Special attention should be paid to the material of manufacture. In cases where the equipment works in a wet or chemically active environment, the choice of stainless steel clamps will be optimal. In less aggressive conditions, galvanized models or variants made of polymers are suitable.

It is equally important to take into account the operating conditions — temperature regimes, humidity, the presence of vibrations or chemicals. All this directly affects the durability and reliability of the clamps.

In 2025, worm-type products made of stainless steel (DIN 3017) will remain the leaders, combining strength, corrosion resistance and ease of use. Models with a reinforced lock for industrial conditions are also relevant.