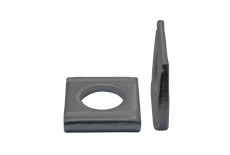

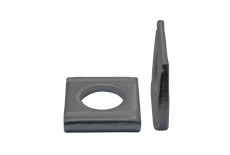

DIN 434 flat Washer

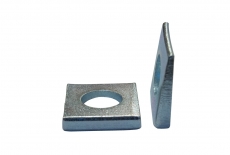

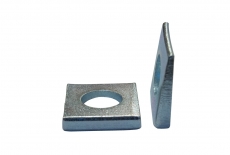

DIN 434 flat Washer DIN 435 Flat washer

DIN 435 Flat washer

Slanted washers are used to compensate for tilting or unevenness of a joint when fastening structures. They are used in situations where it is necessary to ensure that a bolt or nut is pressed evenly against a surface that has an inclination. They are also often used for fixing channels and are classified as fixing and correcting products. The main function of a sloped washer is to evenly distribute the load on an inclined surface, which increases the reliability of the connection. This is especially important in construction, engineering and when installing fasteners on inclined surfaces.

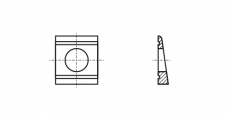

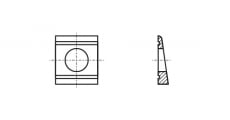

Among the most common standards for inclined washers are DIN 434 and DIN 435. These standards define square-shaped oblique washers with different angles of inclination that are used for various types of structures. They are made of high-strength materials, which allows them to withstand significant loads and ensure fastener stability.

The technical requirements for bevel washers include manufacturing from high-quality steel, which ensures durability and reliability of fastening. The standard sizes of the bevel washers vary depending on the application: from 3 mm to 50 mm. It is important to select the correct slant washers for the size of the bolts and nuts to ensure a secure fastening.

There are several factors to consider in order to select the correct size of the slant washer:

1. Bolt diameter. It is important that the washer hole matches the diameter of the bolt or stud.

2. The angle of the surface. The choice of an oblique washer depends on the angle of the surface. For example, a DIN 434 washer is suitable for an inclined surface with an angle of 8%.

3. Construction material. High-strength washers should be used for fastening to metal or concrete surfaces.

The main factors affecting the price of washers include:

1️⃣ All fasteners in one place: the largest selection in Ukraine.

2️⃣ The more you buy, the lower the price.

3️⃣ When you buy on the website, you get an additional -2% for everything.

4️⃣ Fast delivery of goods both from the warehouse and on order.

5️⃣ A team of experts will quickly help you choose the right hardware.

And you will experience even more benefits by cooperating with DINMARK!

To select and order an oblique washer, you should consider the diameter of the bolt and the angle of the plane. You can order washers through the catalog on the Dinmark website or by contacting a consultant.

At the moment, the Dinmark online store has oblique washers on sale.

The price of DIN 434 washers varies depending on the size and quantity. For retail customers, the price starts at 2 UAH per unit, while discounts are available for bulk orders.

In 2025, DIN 434 and DIN 435 washers are the most popular due to their versatility and high strength.

Enter your email address to follow the Dinmark news