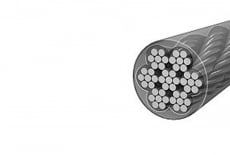

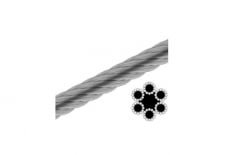

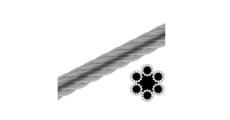

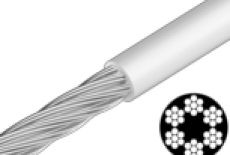

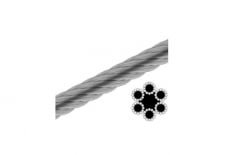

ART 8035 Hard rope, weaving 1x19

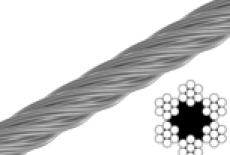

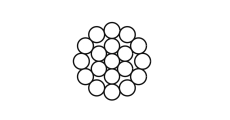

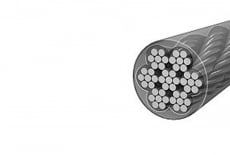

ART 8035 Hard rope, weaving 1x19 ART 8036 Soft stainless rope, braiding 7x19

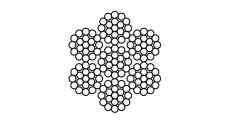

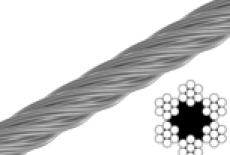

ART 8036 Soft stainless rope, braiding 7x19 DIN 3055 Rope of medium softness, weaving 7x7

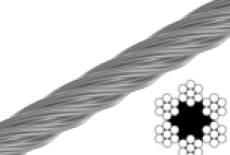

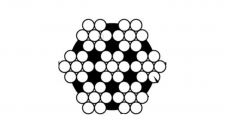

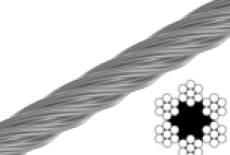

DIN 3055 Rope of medium softness, weaving 7x7 DIN 3060 Rope steel 6x19 + FC

DIN 3060 Rope steel 6x19 + FC ISO 2408 Rope steel 6x12 + FC

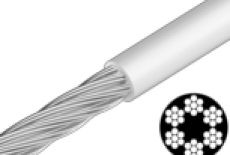

ISO 2408 Rope steel 6x12 + FC DIN 3052 Braiding rope 1x7

DIN 3052 Braiding rope 1x7

Ropes are strong metal ropes consisting of a large number of steel wires twisted together. This construction provides high flexibility while maintaining exceptional tensile strength. The product can be single-layer or multi-layer, with or without a core.

The core performs a cushioning function, ensuring shape stability and reducing internal friction. Its winding can be moistened with grease or galvanized, which increases resistance to corrosion and mechanical wear.

There are several types of them: Flexible (with a large number of wires in a bundle), Rigid (with a smaller number, but thicker wires), With galvanized coating, Without coating, but with grease, etc.

The diameter varies from 1 mm to over 40 mm. Different types of weaving and density determine its characteristics: flexibility, wear resistance, load resistance. When choosing the ideal option, you should consider the scope of application: lifting, traction, fixation, towing.

If you plan buy a metal cable, pay attention to the technical characteristics - they are critical for safety and durability.

Production includes several key stages. First, the steel wire is formed by drawing. Next, the wires are twisted into strands, which are later intertwined into a rope of a given thickness.

If necessary, the product is covered with zinc or another anti-corrosion coating. The final stage is testing for strength, flexibility, wear resistance. This guarantees compliance with GOST or DIN requirements.

These products are used in the following industries: Construction (lifting mechanisms, cranes), Logistics (towing, securing loads), Industry (mechanical drives, equipment), Household (antenna mounting, street lighting)

They are also used in sports, maritime affairs, and the agricultural sector. Due to their high versatility, they remain indispensable in any situation where strength, flexibility and reliability are required.

1️⃣ Huge selection of fasteners: A unique opportunity to find all necessary fasteners in one place - the largest assortment in Ukraine.

2️⃣ Flexible pricing policy: The more you buy, the lower the price you will get, providing favorable conditions for large orders.

3️⃣ Additional discount: When making a purchase on the website, you automatically receive an additional -2% discount on the entire range.

4️⃣ Fast delivery: Enjoy fast delivery of goods both from the warehouse and to order, ensuring the speed and convenience of receiving purchases.

5️⃣ Expert support: Our team of experts is always ready to help you choose the right mount, guaranteeing professional advice and support.

Experience even more benefits by cooperating with DINMARK - your reliable partner in the field of fasteners!

Dinmark offers a wide selection of these products, among which the following are particularly popular:

ART 8035 — general purpose products

ART 8036 — galvanized models for outdoor conditions

DIN 3055 — standard steel products for industrial use

All models meet European standards and have quality certificates. This allows them to be used in responsible facilities without risk. The price of steel ropes in Dinmark remains affordable thanks to direct deliveries and a transparent pricing policy.

Dinmark offers a wide selection of ropes at favorable prices that meet different needs and standards. Our range includes ropes manufactured according to international standards such as ART 8035, ART 8036 and DIN 3055, etc. These ropes are used in a variety of industries, including construction, industry, and transportation. The price of cables depends on the material (steel, stainless steel, synthetic fibers), diameter, length and special coatings for increased wear resistance. For large orders, favorable discounts are available, which allow you to save significantly when buying large batches of products. We also offer delivery throughout Ukraine, which ensures the convenience of receiving the goods.

The best are galvanized products with weaving type 6x19 or 6x36. They combine flexibility and high strength. For external use - only with anti-corrosion protection. The choice depends on the workload, diameter and operating conditions.

To choose the right product, first of all, you need to determine the technical conditions of their use. It is important to consider several key characteristics:

Diameter — it directly affects the load capacity and flexibility. Products with a diameter of up to 6 mm are suitable for light loads. For construction, lifting or transport tasks — from 8 to 20 mm and more.

Type of weaving — the most common are 6x19 and 6x36. The first is universal for most tasks. The second is for cases where high flexibility while maintaining strength is important.

Material — steel products are the basic option. Galvanized models are additionally protected against corrosion, which is critical for outdoor work. For aggressive environments or marine use, it is better to choose stainless steel.

The presence of a core — the textile core provides flexibility, and the steel core provides additional rigidity and resistance to crumpling.

Type of coverage — galvanizing or plastic braiding protects the product from wear and oxidation.

In 2025, you should choose DIN 3055 models with galvanized coating. They are ideal for industrial conditions. ART 8036 flexible products for daily household tasks are also popular. Time-tested reliability is just what you need in the new season.

Enter your email address to follow the Dinmark news