- 1

- 2

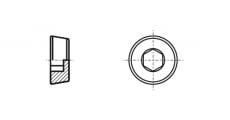

DIN 906 threaded Cap

DIN 906 threaded Cap ART 79 Hexagonal plug with inch thread

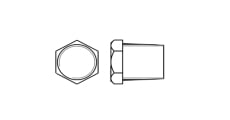

ART 79 Hexagonal plug with inch thread DIN 908 threaded cylindrical Cap

DIN 908 threaded cylindrical Cap DIN 909 conical threaded Cap with hexagon head

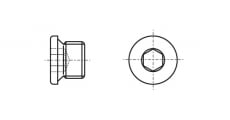

DIN 909 conical threaded Cap with hexagon head DIN 910 threaded Cap

DIN 910 threaded Cap DIN 5586 threaded Cap with hexagon head and flange

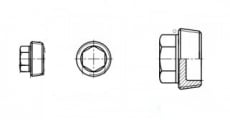

DIN 5586 threaded Cap with hexagon head and flange DIN 7604 threaded Cap with hexagon head and flange

DIN 7604 threaded Cap with hexagon head and flange AN 284 Plug is plastic

AN 284 Plug is plastic

Threaded plugs are elements used to close the end parts of pipelines or openings in structures. Their main function is to prevent leakage of liquid or gas, as well as to protect the inner surface from contamination and corrosion. Structurally, the plug has a threaded connection that allows it to be tightly screwed to the pipeline or other element of the system.

The principle of operation of the plug is simple: thanks to the thread cut on its inner surface, the plug tightly closes the opening or the end of the pipe, ensuring the tightness of the system. It can be made of different materials, such as steel, brass, stainless steel or plastic, which allows you to choose the best option depending on the operating conditions. Plugs are often used in a variety of industries, including construction, industry, and utilities, to keep pipelines and other systems running efficiently.

The dimensions of threaded plugs are critically important for ensuring the correct functioning of pipeline systems and equipment. Choosing the right plug size depends on the diameter of the pipeline and the type of thread. Plugs can have different nominal diameters corresponding to the sizes of the pipes for which they are intended. For example, industrial systems often use plugs with diameters ranging from a few millimeters to several inches.

In addition, plug sizes can vary depending on the type of thread - metric, inch or pipe thread. It is also important to consider the wall thickness of the plug and the material from which it is made, as this affects its tightness and wear resistance. The correct selection of the plug size ensures not only effective sealing, but also safe operation of the system, preventing leaks and possible damage.

The production of threaded plugs is a complex technological process that includes several key stages that ensure their functionality and durability. At the first stage, the appropriate material is selected, in particular steel, brass, stainless steel or plastic, depending on the operating conditions and requirements for corrosion resistance.

Next, the material is processed on metalworking machines, where it is shaped according to the specified parameters. The manufacturing process involves precise cutting of the thread, which must meet standards and ensure the tightness of the connection. For this, specialized tools and equipment are used, which allows to achieve high precision and quality of cutting.

Thus, the production of threaded plugs is a complex and multifaceted process that requires precision at all stages to ensure their reliability and durability in various operating conditions.

Threaded caps and plugs are widely used in various spheres of industry and everyday life due to their versatility and functionality.

In industrial systems, plugs help maintain proper pressure levels and protect internal components from contamination, corrosion, and mechanical damage. In construction, they are often used to seal pipe systems, or to temporarily close openings until installation work is completed.

In the utility industry, plugs are used to close water supply and sewage systems, which ensures their uninterrupted operation and maintains the cleanliness of the system. In the automotive and oil and gas industries, threaded plugs also play an important role in sealing various components and assemblies, helping to ensure their reliable operation.

1️⃣ Huge selection of fasteners: A unique opportunity to find all necessary fasteners in one place - the largest assortment in Ukraine.

2️⃣ Flexible pricing policy: The more you buy, the lower the price you will get, providing favorable conditions for large orders.

3️⃣ Additional discount: When making a purchase on the website, you automatically receive an additional -2% discount on the entire range.

4️⃣ Fast delivery: Enjoy fast delivery of goods both from the warehouse and to order, ensuring the speed and convenience of receiving purchases.

5️⃣ Expert support: Our team of experts is always ready to help you choose the right mount, guaranteeing professional advice and support.

Experience even more benefits by cooperating with DINMARK - your reliable partner in the field of fasteners!

The best threaded plugs are distinguished by the quality of materials, manufacturing accuracy and compliance with standards. Choose those made of stainless steel or brass for better durability and corrosion resistance.

To choose and order threaded plugs in Dinmark, focus on product specifications, materials and compliance with your technical requirements. Consultation with specialists and review of reviews add will be able to make the right choice.

In 2025, look out for corks with innovative materials and coatings that increase their durability and reliability.

Enter your email address to follow the Dinmark news