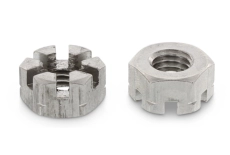

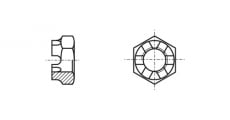

DIN 935 Crown nut

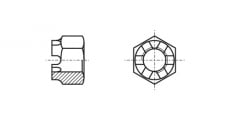

DIN 935 Crown nut Cap nut

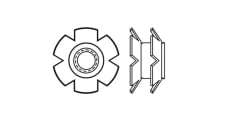

Cap nut DIN 937 Low crown nut

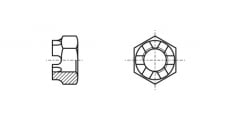

DIN 937 Low crown nut DIN 979 Crown nut

DIN 979 Crown nut

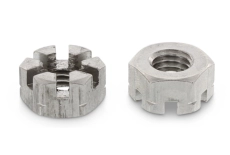

Socket nuts are a special type of nuts used to create reliable and detachable connections. Their peculiarity lies in the presence of cutouts or slots at one end, which create a "crown". Thanks to these slots, these nuts can be fixed with a cotter pin or wire, which provides additional fixation and prevents self-tightening.

There are several types of crown nuts that differ in shape, size, and materials. The most common ones are made of steel, stainless steel, or brass, which provides high strength and corrosion resistance. Some nuts may have a special coating that further protects them from aggressive environments.

Socket nuts are made of high-strength steel, often with an anti-corrosion coating to increase resistance to environmental influences. They have a characteristic design with slots or crowns that allow the use of cotter pins for additional fixation. This ensures reliable fastening even in cases of vibrations or variable loads. The production of such nuts is regulated by strict standards, such as DIN 935 or GOST 5918-73, which define dimensions, materials, quality requirements and test methods. These standards ensure that castellated nuts meet high safety and reliability requirements, making them popular in the aviation, automotive, and mechanical engineering industries.

A castellated nut is fastened by screwing it onto a threaded rod or bolt, after which it is securely fixed with a cotter pin. First, the nut is screwed on to the required tightening torque, with the crown teeth aligned with the hole in the rod or bolt. Next, a cotter pin is passed through this hole, the ends of which are bent to prevent the nut from reversing. This method of fastening ensures a secure and stable connection, preventing spontaneous loosening of the nut under the influence of vibrations or dynamic loads.

1️⃣ All fasteners in one place: the largest selection in Ukraine.

2️⃣ The more you buy, the lower the price you get.

3️⃣ When buying on the website, you additionally receive -2% on everything.

4️⃣ Fast delivery of goods both from the warehouse and to order.

5️⃣ A team of experts will quickly help you choose hardware.

And you will experience even more benefits by cooperating with DINMARK!

The castellated nut is used in a variety of industries, including mechanical engineering, automotive and construction. It is ideal for applications that require high resistance to self loosening and high load capacity.

Prices for these nuts can vary depending on the size, material, and manufacturer. Retail prices typically range from a few hryvnias to tens of hryvnias per unit, while wholesale prices can be significantly lower due to discounts for large quantities. We recommend contacting the supplier to obtain the most current prices.

In 2025, the most popular nuts are those made of stainless steel and with a high level of strength, such as nuts of DIN 985 and DIN 1587 standards. They are in demand due to their durability and excellent performance.

To select and order a castellated nut from Dinmark, first determine the required size, material and standard of the nut. Then contact our manager or use our online catalog to select the appropriate model. It is important to check availability and possible delivery options before placing your order.

Enter your email address to follow the Dinmark news