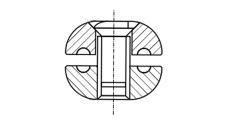

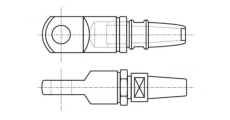

ART 8445 Cable end fitting

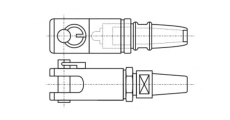

ART 8445 Cable end fitting ART 8447 Cable end fitting

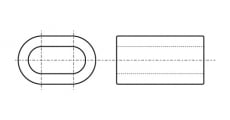

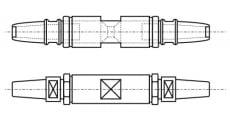

ART 8447 Cable end fitting 3S200 Barrel-shaped cable clamp

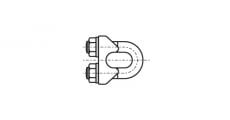

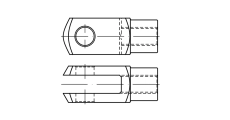

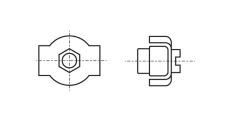

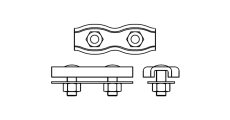

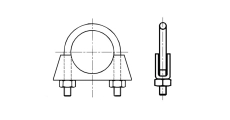

3S200 Barrel-shaped cable clamp DIN 1142 Clamp with two nuts

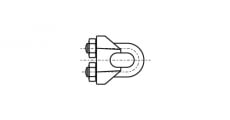

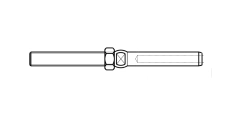

DIN 1142 Clamp with two nuts DIN 741 Cable clamp with two nuts

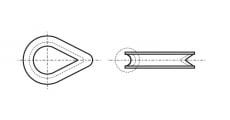

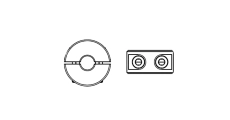

DIN 741 Cable clamp with two nuts DIN 6899 Thimble

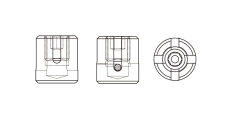

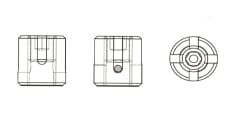

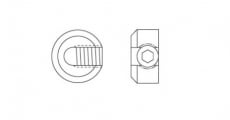

DIN 6899 Thimble DIN 3093 Cable clamp

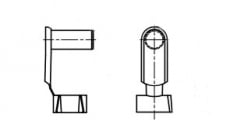

DIN 3093 Cable clamp DIN 71752 G Fork head

DIN 71752 G Fork head ART 8620 Cable lug with left-hand thread

ART 8620 Cable lug with left-hand thread ART 8322 Norseman with ring

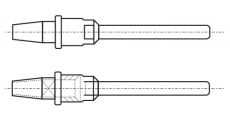

ART 8322 Norseman with ring ART 8449 Tip for rope

ART 8449 Tip for rope ART 8323 Norseman with fork

ART 8323 Norseman with fork ART 8324 Cable tip

ART 8324 Cable tip ART 8326 Norseman with carving

ART 8326 Norseman with carving ART 8330 SIMPLEX cable clamp with one nut

ART 8330 SIMPLEX cable clamp with one nut ART 8331 DUPLEX cable clamp with two nuts

ART 8331 DUPLEX cable clamp with two nuts ART 8374 Finger rigging

ART 8374 Finger rigging ART 8424 Clip for a cross cable

ART 8424 Clip for a cross cable ART 8425 Cross cable clamp

ART 8425 Cross cable clamp ART 8426 DOUBLE cable clamp

ART 8426 DOUBLE cable clamp ART 8427 Clamp for a screw cable

ART 8427 Clamp for a screw cable AN 116 Pipe clamp

AN 116 Pipe clamp AN 124 Pin with spring protection

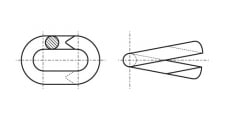

AN 124 Pin with spring protection AN 92 Connecting ring

AN 92 Connecting ring

Cable clamps are fasteners designed to securely connect or fix the ends of metal ropes and cables. They allow you to create a loop or connect two cables without complicated tools or welding. The main advantage is ease of assembly and disassembly while maintaining high strength of the connection.

Such products are especially relevant in industries where reliable but flexible fastening is important: in freight transportation, construction, shipping, agriculture and assembly work. Cable clamp used in cases where it is necessary to fasten the rope quickly and safely without damaging its structure.

In addition, these hardware are noted for their durability. Most models are made of galvanized or stainless steel, which ensures resistance to corrosion and aggressive environments. Their design is designed for multiple use.

Supplier Dinmark offers a wide range rope clamps, which meet international standards:

DIN 1142 — classic steel ones with two nuts

DIN 741 — universal, with a saddle

DIN 6899 — bushings to protect the cable loop

DIN 3093 — aluminum crimp sleeves for pressing

All models are available in different sizes for ropes with a diameter of 2 to 20 mm. This allows you to choose the best option for any conditions — from light household tasks to industrial loads. Buy cable clamps in Dinmark is a guarantee of conformity, quality and safety.

The main types of clamps: — Classic bolted (DIN 1142, DIN 741) — universal, strong, easy to install

- Bushes (DIN 6899) - protect the cable from bending at the loop

— Crimping sleeves (DIN 3093) — for permanent connection by means of pressing

Clamps have a simple but reliable design. It consists of a base (saddle), a clamping bracket and two nuts. Thanks to this, the clamp is fixed tightly and evenly over the entire contact area. Material — galvanized or stainless steel. The coating ensures a long service life even in a humid environment.

The dimensions are determined according to the diameter of the cable. A 6 mm clamp is required to fix a 6 mm cable. It is important to follow the instructions regarding the number of clamps per connection. Most types of cables require at least three clamps.

The choice of a cable clamp depends on several key factors: the type of cable, its diameter, as well as the operating conditions. First of all, you need to determine the material of the cable - for steel cables, it is better to choose clamps made of stainless steel or a strong alloy, which will ensure high resistance to corrosion.

It is also important to pay attention to the size of the clamp - it must correspond to the diameter of the cable to ensure a reliable and strong connection. For most applications, clamps complying with international standards such as DIN or ISO are used, guaranteeing their quality and reliability.

1️⃣ Huge selection of fasteners: A unique opportunity to find all necessary fasteners in one place - the largest assortment in Ukraine.

2️⃣ Flexible pricing policy: The more you buy, the lower the price you will get, providing favorable conditions for large orders.

3️⃣ Additional discount: When making a purchase on the website, you automatically receive an additional -2% discount on the entire range.

4️⃣ Fast delivery: Enjoy fast delivery of goods both from the warehouse and to order, ensuring the speed and convenience of receiving purchases.

5️⃣ Expert support: Our team of experts is always ready to help you choose the right mount, guaranteeing professional advice and support.

Experience even more benefits by cooperating with DINMARK - your reliable partner in the field of fasteners!

Cable clamps provide a reliable and safe connection of cables, which makes them important in various industrial and construction areas. They are easy to install, suitable for different types of cables and materials, which allows them to be used in many industries. Clamps are made of strong and corrosion-resistant materials, which ensures durability and reliability of connections. In addition, they are economical and do not require frequent replacement, making them a good choice for long-term use.

Cable clamp price withdepends on the size, material and type of product. For example, standard DIN 741 for 6 mm cable costs from UAH 5 to 10 per unit. The cost of DIN 6899 bushings starts at UAH 3, and DIN 3093 crimp sleeves start at UAH 2. Dinmark has a flexible system of discounts for bulk orders.

In 2025, DIN 1142 clamps remain the most popular — they are versatile, strong and suitable for most tasks. DIN 6899 bushings are also often chosen in conjunction with clamps, as this allows for longer cable life.

Enter your email address to follow the Dinmark news