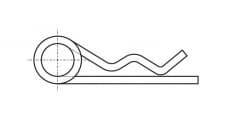

DIN 11024 Spring cotter pin Form D

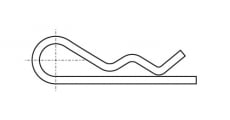

DIN 11024 Spring cotter pin Form D DIN 11024 Spring cotter pin Form E

DIN 11024 Spring cotter pin Form E

Spring cotter pins are used to fix axes, shafts and pins that are used in technology, equipment and structures. plows) Construction and metal structures - used for installation and strengthening of structures where additional fixation is required.

The main advantage of spring cotter pins is their simple design, which allows you to quickly install and remove fasteners. The main characteristics of cotter pins include materials of manufacture, including galvanized, stainless and carbon steel. Structurally, they consist of a specially shaped curved wire that ensures a tight fit to the part being fixed. Cotter pin sizes vary depending on thickness and length, which allows you to choose the best option for a specific task. Among the main advantages are high strength, corrosion resistance, especially in stainless steel models, as well as the possibility of repeated use without loss of functionality. Spring cotter pins have a simple but effective mechanism of action. They are inserted into special holes in the shaft or pin and are securely fastened due to their elasticity.

The range of spring cotter pins is represented by various types that meet international standards. The most popular models:

DIN 11024 form E – a classic model with a round head, which is used for fastening parts in agricultural machinery and mechanisms with high loads.

DIN 11024 form D – has a straight shape with an additional bend, which provides enhanced fixation.

Both options are widely used in industry because they are easy to use and highly reliable.

These fasteners are used to provide a secure connection to parts that may become dislodged or accidentally become detached. The main areas of application are as follows. Fixation of axles, pins and shafts in mechanical units. Fastening structural elements in construction. Use of the transport industry for fastening suspension parts and other components. Agricultural machinery – fixation of moving parts of agricultural machines. Due to their ease of installation and dismantling, spring cotter pins are an indispensable element for quickly connecting parts in many industries.

1️⃣ Convenient solution for fasteners: the largest range of all types of fasteners in Ukraine.

2️⃣ Savings with every order: the more purchases, the better the price for the product.

3️⃣ Bonuses for online purchases: additional -2% discount on all products when ordering through the website.

4️⃣ Fast delivery to your feet: if the product is in stock, individual orders are also possible.

5️⃣ Professional support: a team of experts is ready to help you choose the necessary hardware quickly and efficiently.

Get even more benefits when shopping with DINMARK!

To buy spring cotter pins, first of all, you should pay attention to the material of manufacture, type of coating (galvanized or stainless), dimensions and compliance with DIN standards.

To choose the right hardware, it is necessary to take into account their technical characteristics. First of all, an important material of manufacture: stainless steel provides high corrosion resistance and is suitable for use in aggressive environments, galvanized steel has additional protection against rust, and carbon steel provides high strength under significant loads. You should also pay attention to the diameter and length of the cotter pin, which must correspond to the diameter of the hole in the part to ensure reliable fastening. An important parameter is the shape of the cotter pin - standard models are used for general installation work, while reinforced versions are suitable for increased loads. When choosing, it is necessary to take into account the design of the product: cotter pins with widened ends simplify installation and dismantling, and models with increased elasticity better hold parts in a fixed position.

The most popular models are products according to DIN 11024 forms E and D. They have high strength and are widely used in various fields. Spring cotter pins are important fastening elements widely used in mechanical engineering, construction, agriculture and other industries. They provide reliable fixation of parts, preventing their displacement or accidental separation. If you are looking for high-quality hardware, buying them from Dinmark is the right decision. We offer a large selection, affordable prices and fast delivery.

Enter your email address to follow the Dinmark news