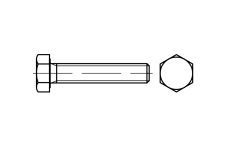

Hexagon head Bolts

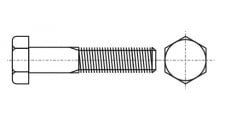

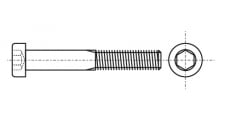

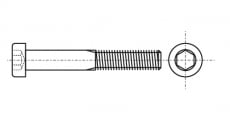

Hexagon head Bolts Bolts with internal hexagon

Bolts with internal hexagon HV structural bolts

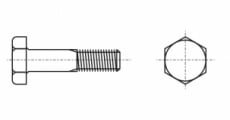

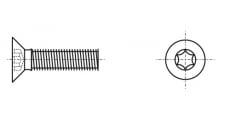

HV structural bolts Countersunk head bolts

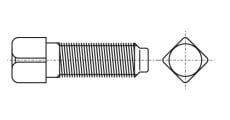

Countersunk head bolts Square head / headrest Bolts

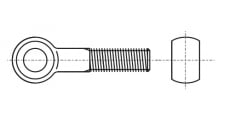

Square head / headrest Bolts Bolts with a ring

Bolts with a ring Bolts with an inch thread

Bolts with an inch thread T-shaped bolts

T-shaped bolts

A bolt is an indispensable part for fastening, one of the types of threaded fasteners, made in the form of a cylindrical rod with a head. On a cylindrical part of a bolt the carving on which in the course of installation the nut is screwed is put. The thread can be made not on the entire plane of the rod, but only on a separate part of it, and the thread can be inch or metric, right or left.

By means of a head of a bolt support of bolted connection on the elements fastening in a design is carried out. Tightening a tight bolted connection is very difficult to do by hand, so if you need a strong and reliable connection, you will need to use special tools, such as a wrench, the size of the bolt head. The bolts can have different sizes of cylindrical rod and head shape.

By shape and type of head bolts are:

Countersunk head bolts - this type of bolt is used if it is necessary to hide the connecting parts of the structure as much as possible, as its head is able to hide in the connecting material without compromising the overall aesthetic appearance of the structure. So bolts with a countersunk head are often used in instrument making, in mechanical engineering, as furniture fastening and in some other spheres of production.

Semicircular head bolts - this type of bolts is used to connect soft structural elements of materials such as particleboard, plywood, MDF and others.

Bolts with a multifaceted head (hexagonal or quadrilateral) - is considered the most popular and versatile type of bolts. Widely used in many industries as building fixtures, in mechanical engineering and instrumentation, in everyday life, etc.

Bolts with a flange - have a press washer of relief type or flat type. Mainly used for fastening parts that can be subjected to regular dynamic and vibratory loads.

Hinged bolt - hinged has a hole that is used mainly to adjust the traction force in the mechanisms.

Anchor bolt - eyebolt - with a head in the form of a ring or hook. It is used when it is necessary to lift various materials and loads, as well as to fix individual structural elements in construction. The material for making eyebolts is alloy steel.

The area of application of bolts is very large. So stainless steel bolts are used in various industries, in mechanical engineering and instrument making, in construction in the home and more.

Various materials are now used to make bolts, from high-strength polymers to metal, but stainless steel bolts are considered to be more popular and practical.

According to the mechanical characteristics, there are 11 classes of bolt strength: 3.6; 4.6; 4.8; 5.6; 5.8; 6.6; 6.8; 8.8; 9.8; 10.9; 12.9. If we consider in more detail the characteristics of the strength classes, we obtain:

Bolts with a strength class in the range of 4.8-5.8 - do not have high strength, prone to rupture at high loads, but bolts with a strength class of 5.8, in contrast to 4.8, are able to withstand loads stronger than 20%.

Bolts with strength class 8.8 - compared to the characteristics of bolts of class 4.8, can withstand twice the load. Stainless steel bolts can be used as responsible fasteners.

Bolts with strength class 8.8; 10.9; 12.9 - high-strength bolts, capable of withstanding 2.7 times more destructive impact than bolts with 4.8 strength class. High-strength bolts are used in critical mechanisms and structures, in lifting devices, as well as in structures that require periodic disassembly.

Depending on the direct purpose of the bolts are divided into:

Road bolts - are used for connection and installation of various road, enclosing metal constructions and designs. Stainless steel road bolts are made of strength class 8.8.

Bolts machine-building - stainless steel, widely used in mechanical engineering and instrumentation, in various construction industries, in the automotive industry, etc. They are made of medium and high-strength steel, corresponding to strength classes 5.8-12.9.

Ploughshare bolts - mainly used in the connection, fastening and installation of suspended structures and equipment. Stainless steel ploughshare bolts are made of stainless steel food grade A2 and acid-resistant A4 steel.

Furniture bolts - common in the production and installation of various furniture, as well as used in some construction processes. Stainless steel furniture bolts are made of food grade A2 and acid-resistant A4 steel.

For example, a bolt with a hexagonal head DIN 933, ISO 4017, PN85 M-82105, GOST 7798-70 - a bolt corrosion-proof with a full carving, diameter M2-M64, length of a bolt 4 - 340 mm. Stainless bolts with a hexagonal head are used to connect parts and elements of structures and mechanisms in instrumentation, mechanical engineering and construction. Stainless bolts are made of stainless food and acid-resistant steel A4 and A2 and made of high-strength steel with strength classes 8.8, 10.9 and 12.9; and steel for bolts can have a special anti-corrosion coating, which can be made by hot-dip galvanizing or galvanizing.

Hexagon head bolt DIN 931, DIN 601, ISO 4014, PN85 M-82101, GOST 7798-70 - stainless steel hexagon bolt with incomplete thread. Stainless bolts with a hexagonal head and an incomplete carving for fastening of several details of designs and mechanisms in device, mechanical engineering, in a life and in construction are used. Hexagon bolts are made of stainless food and acid-resistant steel A2 and A4 and high-strength steel, corresponding to strength classes 8.8, 10.9 and 12.9; and also steel for production of bolts can have a special anticorrosive covering which can be executed by hot galvanizing or galvanic galvanizing.

Enter your email address to follow the Dinmark news