-a2-samoriz-z-napivkruhlou-holovkou-i-burom-ph--12454.webp)

-a2-samoriz-z-napivkruhlou-holovkou-i-burom-pz-12000.webp)

-a2-samoriz-z-napivkruhlou-holovkou-i-burom-pid-torx-12972.webp)

-cynk-samoriz-z-napivkruhlou-holovkou-i-burom-pid-torx-8207.jpg)

-cynk-samoriz-z-napivkruhlou-holovkou-i-burom-sq-5518.jpg)

-cynk-samoriz-z-napivkruhlou-zubchastou-holovkou-i-burom-sq-5516.jpg)

-cynk-chornyy-samoriz-z-napivkruhlou-holovkou-i-burom-ph-5520.jpg)

-a2-samoriz-z-napivkruhlou-holovkou-i-burom-sq-12971.webp)

-a4-samoriz-z-napivkruhlou-holovkou-i-burom-pz-12003.webp)

-a4-samoriz-z-napivkruhlou-holovkou-i-burom-pid-torx-12973.webp)

-samoriz-z-napivkruhlou-holovkou-i-burom-nerzhaviuchyy-a2-a4-12959.webp)

- 1

- 2

-samoriz-z-napivkruhlou-holovkou-i-burom--2531.jpg) DIN 7504 M (N) Self-tapping screw with semicircular head and drill

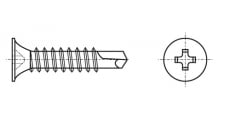

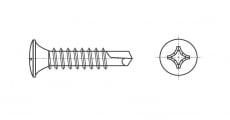

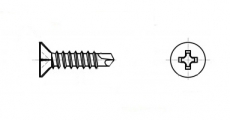

DIN 7504 M (N) Self-tapping screw with semicircular head and drill DIN 7504 O Self-tapping screw with countersunk head and drill

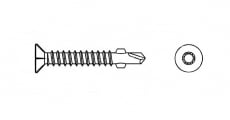

DIN 7504 O Self-tapping screw with countersunk head and drill DIN 7504 P Self-tapping screw with countersunk head and drill

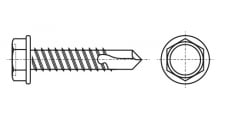

DIN 7504 P Self-tapping screw with countersunk head and drill DIN 7504 K Self-tapping screw with hex head and drill

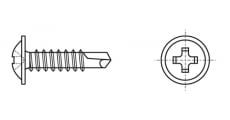

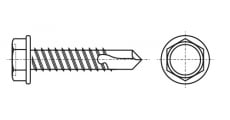

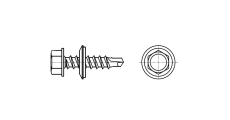

DIN 7504 K Self-tapping screw with hex head and drill DIN 7504 T Self-tapping screw with semicircular head and press washer with drill

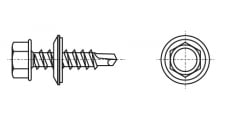

DIN 7504 T Self-tapping screw with semicircular head and press washer with drill AN 212 Self-tapping screw with hex head and EPDM washer

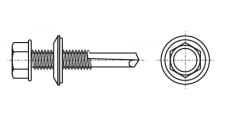

AN 212 Self-tapping screw with hex head and EPDM washer DIN 7504 KO hexagon Self-tapping screw with drill and EPDM washer

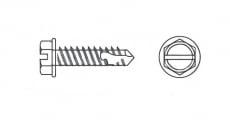

DIN 7504 KO hexagon Self-tapping screw with drill and EPDM washer DIN 7504 KL Self-tapping screw with hex head and drill and straight slot

DIN 7504 KL Self-tapping screw with hex head and drill and straight slot ISO 15480 K Self-tapping screw with hexagon head

ISO 15480 K Self-tapping screw with hexagon head DIN 7504 Q Self-tapping screw with semi-hollow head and drill PH

DIN 7504 Q Self-tapping screw with semi-hollow head and drill PH AN 209 Self-tapping screw with countersunk window head

AN 209 Self-tapping screw with countersunk window head AN 211 Self-tapping screw with hexagon head and EPDM washer

AN 211 Self-tapping screw with hexagon head and EPDM washer-8461.jpg) STITCHER screws (Screws)

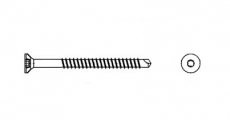

STITCHER screws (Screws) ART 9040 Super-Drill CSK wood screw driver with countersunk head and TORX drill bit

ART 9040 Super-Drill CSK wood screw driver with countersunk head and TORX drill bit AN 208 Self-tapping screw with countersunk head and drill for drywall metal

AN 208 Self-tapping screw with countersunk head and drill for drywall metal DIN 7504-WM self-tapping Screw with countersunk head and drill

DIN 7504-WM self-tapping Screw with countersunk head and drill DIN 7504-Wr self-tapping Screw with countersunk head and window drill with notchesDIN 7504-WMr Self-tapping screw with countersunk head and drill bit

DIN 7504-Wr self-tapping Screw with countersunk head and window drill with notchesDIN 7504-WMr Self-tapping screw with countersunk head and drill bit

-a2-samoriz-z-napivkruhlou-holovkou-i-burom-ph--12454.webp)

-a2-samoriz-z-napivkruhlou-holovkou-i-burom-pz-12000.webp)

-a2-samoriz-z-napivkruhlou-holovkou-i-burom-pid-torx-12972.webp)

-cynk-samoriz-z-napivkruhlou-holovkou-i-burom-pid-torx-8207.jpg)

-cynk-samoriz-z-napivkruhlou-holovkou-i-burom-sq-5518.jpg)

-cynk-samoriz-z-napivkruhlou-zubchastou-holovkou-i-burom-sq-5516.jpg)

-cynk-chornyy-samoriz-z-napivkruhlou-holovkou-i-burom-ph-5520.jpg)

-a2-samoriz-z-napivkruhlou-holovkou-i-burom-sq-12971.webp)

-a4-samoriz-z-napivkruhlou-holovkou-i-burom-pz-12003.webp)

-a4-samoriz-z-napivkruhlou-holovkou-i-burom-pid-torx-12973.webp)

-samoriz-z-napivkruhlou-holovkou-i-burom-nerzhaviuchyy-a2-a4-12959.webp)

Self-tapping screws with a drill are an advanced type of fasteners that play an important role in modern fastening systems. Basically, these screws are designed to fasten strong materials without preliminary drilling (for example, metal screws with drill). Let's take a look at how drill screws stand out from other fasteners and how their unique characteristics ensure optimal results in a variety of applications.

Self-tapping screws with a drill are characterized by their extreme resistance to corrosion and high performance. The main characteristics of these fasteners make them indispensable in a number of demanding applications:

1. Corrosion resistance

The stainless steel used in the manufacture of drill screws ensures that these fasteners can withstand moisture and aggressive environments.

2. Versatility of use

Stainless steel screws are suitable for use in a variety of materials, including metal, wood, aluminum and plastic.

3. Efficiency thanks to the drill

The integrated drill simplifies the installation process by allowing the screws to penetrate the material quickly and easily.

4. Excellent appearance

Stainless steel adds an attractive aesthetic appearance and prevents stains or defects, which is especially important in the production of furniture or other products with high appearance requirements.

There is a wide variety of drill screws, and it is important to determine the optimal type depending on the specific tasks and requirements of the construction. Let's take a look at some of the main types of drill screw heads:

This type of head allows for easier installation into the material without the risk of tool breakage.

Thanks to its shape, this type of head allows for fast and easy screwing of the screw, making them ideal for tasks where time is of the essence.

This type of head has a built-in press washer to help distribute the load and increase the stability of the fixation, providing additional protection against loosening.

Ideal for use in areas where an evenly distributed contact surface is important and to prevent scratches or damage.

Reinforced drill screws for metal are entering the fastening market with exceptional performance and a higher level of productivity. This type of screws is equipped with a special drill bit that is characterized by increased strength and a chisel-shaped design.

Reinforced screws are mainly used in construction to ensure a strong and reliable connection, as the reinforced drill bit allows you to cut through strong material with particular ease and without the risk of breaking.

1️⃣ Convenient fastening solution: the largest range of all types of fasteners in Ukraine.

2️⃣ Savings with every order: the more purchases you make, the better the price for the product.

3️⃣ Bonuses for online purchases: an additional -2% discount on all products when ordering through the website.

4️⃣ Fast delivery at your doorstep: if the goods are in stock, individual orders are also possible.

5️⃣ Professional support: a team of experts is ready to help you choose the right hardware quickly and efficiently.

Get even more benefits when shopping with DINMARK!

You can buy these screws in our online store Dinmark.

High-quality steel materials, heat treatment to increase strength and precise shaping of the drill bit.

The use of special steel alloys, grinding, corrosion protection coating and advanced technologies ensure reliability and efficiency.

Enter your email address to follow the Dinmark news