Exhaust Rivet with a flat flange

Exhaust Rivet with a flat flange Exhaust Rivet with flat enlarged flange

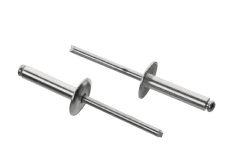

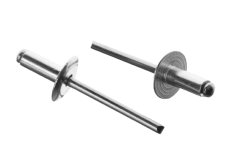

Exhaust Rivet with flat enlarged flange Stainless steel rivets with a secret side

Stainless steel rivets with a secret side Exhaust Rivet tight with a flat flange

Exhaust Rivet tight with a flat flange Exhaust Rivet sealed with a flat enlarged flange

Exhaust Rivet sealed with a flat enlarged flange Exhaust Rivet tight with a flat secret flange

Exhaust Rivet tight with a flat secret flange Trebol Rivet

Trebol Rivet Four-petalled Rivet

Four-petalled Rivet Hard Lock Rivet

Hard Lock Rivet MULTIGRIP multi-clamp Rivet

MULTIGRIP multi-clamp Rivet The Rivet is strengthened with the double lock, constructive

The Rivet is strengthened with the double lock, constructive Rivet for a tree corrugated

Rivet for a tree corrugated

Blind rivets are one of the most reliable types of fastening used in various industries. In mechanical engineering, they are used to connect metal parts, ensuring the strength of structures. decorative elements In construction, this type of fastener allows you to reliably connect sheet materials such as metal, plastic and composite panels.

The main feature of blind rivets is their ability to create a strong connection without the need to access the back of the part. They consist of a body and a rod, which is removed during installation, forming a tight mount. They are made from different materials: aluminum provides lightness and anti-corrosion protection, stainless steel is suitable for aggressive environments, and copper is used for electrical connections. Due to their ease of installation, they reduce the time required to assemble structures and improve their durability.

There are several main types of blind rivets on the market, each of which has its own purpose. Blind rivet with flat countersunk shoulder. – provides a flat surface after installation, used where aesthetic appearance and the absence of protruding elements are important. Exhaust with a flat enlarged collar – has a wider shoulder, which reduces pressure on the material and is suitable for joining soft or fragile surfaces. The exhaust is sealed with a flat collar – creates a tight connection, does not allow liquid and air to pass through, ideal for use in wet conditions. MULTIGRIP multi-clamp – a universal rivet that allows you to work with materials of different thicknesses without the need to change the length. Hard Lock – reinforced structural hardware with high strength, ensuring reliable connection even in critical structures. The choice of the appropriate type depends on the material, operating conditions and the required level of strength.

Due to their characteristics, blind rivets are widely used for joining thin-walled materials where other types of fasteners are not suitable. They are effective for installing ventilation and facade structures, assembling metal profiles and car bodies, and repairing equipment. Their ability to provide a strong, permanent connection makes them popular in manufacturing processes and installation applications.

1️⃣ Convenient solution for fasteners: the largest range of all types of fasteners in Ukraine.

2️⃣ Savings with every order: the more purchases, the better the price for the product.

3️⃣ Bonuses for online purchases: additional -2% discount on all products when ordering through the website.

4️⃣ Fast delivery to your feet: if the product is in stock, individual orders are also possible.

5️⃣ Professional support: a team of experts is ready to help you choose the necessary hardware quickly and efficiently.

It's worth buying Blind Rivets and getting more benefits from DINMARK!

The choice of the best blind rivets depends on the base material, operating conditions and the loads they must withstand.

Aluminum – lightweight, corrosion-resistant, ideal for thin metals and structures that are not subject to significant mechanical loads. They are often used in the automotive industry, ventilation systems and light frame structures. Steel– much stronger than aluminum and can withstand high mechanical loads. Used in construction, mechanical engineering and installation of heavy structures. Stainless – the best choice for humid and aggressive environments, because they are not subject to corrosion. They are used in shipbuilding, the food industry and other industries where the durability of the connection is important. Thus, if lightness of construction is important, choose aluminum; if you need strength, choose steel; and for working in difficult conditions, stainless rivets are best suited.

To buy blind rivets, first of all, you should pay attention to the material. Aluminum rivets are lightweight and corrosion-resistant, while steel rivets are strong and can withstand heavy loads. Stainless steel is ideal for wet conditions, while copper options are suitable for electrical structures. The diameter of the product must correspond to the hole in the parts, and the length must ensure a reliable connection. The type of bead is also important: standard - for universal use, enlarged - for soft materials, hidden - for a flat surface. The operating conditions should also be taken into account. For the external environment, it is better to choose stainless steel fasteners, and for mechanical engineering – steel or combined options.

Hardware made of stainless steel and aluminum, which have high corrosion resistance, will remain popular. Models with improved adhesion characteristics are also relevant for complex installation work.

Enter your email address to follow the Dinmark news