ISO 13918-IT 4.8 copper-plated welded Sleeve

Copy the product nameAssortment

Technical characteristics

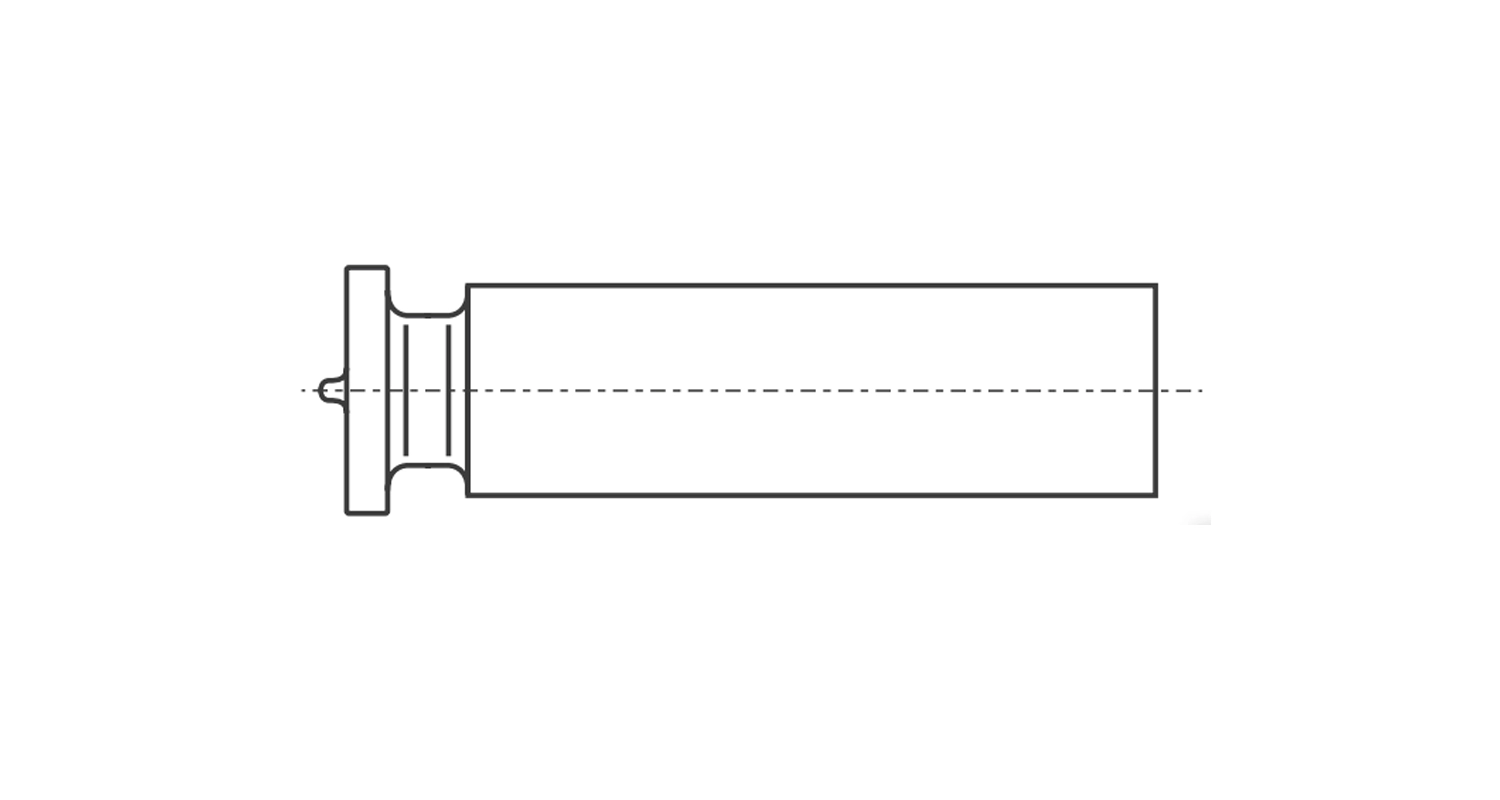

Welded Sleeve is a type of fastening that is used to create a fastening unit on sheet metals, to which they are mounted by rapid welding by capacitor or butt welding. A thin tip at the base of the stud is required, firstly as a material for melting, and secondly to form the distance between the materials for forming a welding bath evenly over the entire plane of the base of the stud.

The scope of us is very wide, but the greatest application has been found in the production of electrical equipment.

The material is high-strength steel. The high strength class 4.8 allows the use of bolts in highly loaded connections.

Plating - The copper plating of the pin creates low contact resistance and better current conduction, which greatly speeds up the welding process. Also, the copper coating improves the characteristics of the welds, increasing the resistance to tearing and shock loads.

Warning

Warning

Delivery

Delivery

Payment

Payment

Warranty

Warranty

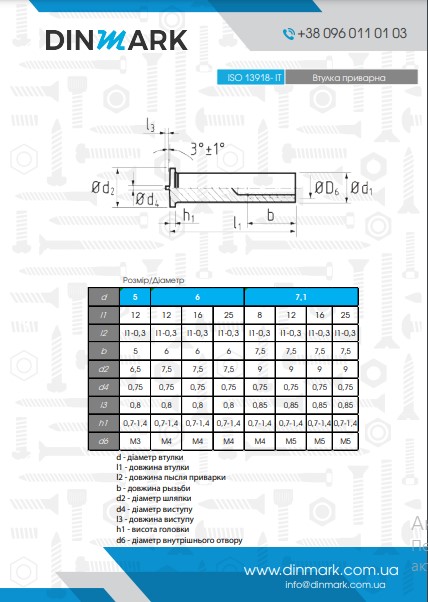

Specifications |

|

| Standard | ISO 13918-ITDIN 32501 |

| Material | Stal |

| Strength class | 4.8 |

| Coating | Copper |

| Diameter, mm | 567.18 |

| Length, mm | 68101216202540 |

| Packaging, pcs. | 1002505001000 |

| Type of carving | Full |

| Thread type | Metric |

| Threading step, mm | 0.811.25 |

| Popular name | Welded hairpin |

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

more шт

and save money

Buy and order