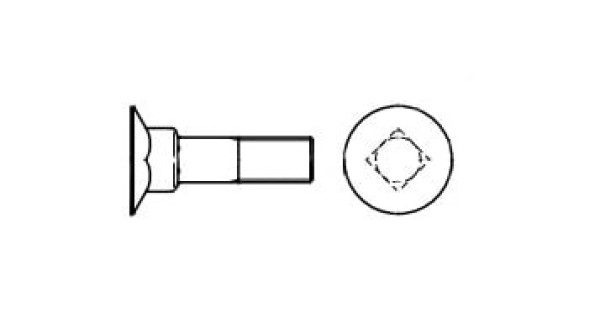

A DIN 605 countersunk screw is a type of fastener used to join components where the screw head needs to be concealed. It has a cylindrical head with an internal hexagonal socket, allowing it to be tightened with an Allen key. This type of screw is widely used in mechanical engineering, furniture manufacturing, and other industries where the appearance of the joint is important.

Technical Characteristics of DIN 605

- Material: Typically made of steel (carbon or alloy steel), but can also be made of stainless steel or other metals, depending on the operating conditions.

- Coating: To protect against corrosion and improve appearance, it can be galvanized, phosphated, or have other types of coatings.

- Strength class: Determines the strength of the screw and is selected depending on the load it must withstand.

- Manufacturing accuracy: Determined by the appropriate standard and ensures a reliable connection of components.

- Dimensions: Thread diameter, length, head height, and other dimensions are regulated by the DIN 605 standard.

Strength Class DIN 605

The strength class of a screw indicates its ability to withstand certain loads. For DIN 605 screws, strength classes from 4.6 to 12.9 are typically used. The higher the strength class, the greater the force the screw can withstand.

Fastener Group: Countersunk Screw DIN 605

DIN 605 screws belong to the group of general-purpose fasteners and are used in a wide range of applications.

Materials for Manufacturing DIN 605

- Steel: The most common material for manufacturing DIN 605 screws.

- Stainless steel: Used in aggressive environments where high corrosion resistance is required.

- Other metals: Can be used for special applications, such as brass or bronze.

Applications of DIN 605

DIN 605 screws are widely used in:

- Mechanical engineering: For joining parts of machines and mechanisms.

- Furniture industry: For joining furniture elements.

- Instrument making: For assembling instruments and devices.

- Construction: For fastening light structures.

Advantages of using DIN 605 screws

- Aesthetic appearance: The concealed head makes the joint more neat.

- Reliability: Provides a strong and reliable connection of components.

- Versatility: Can be used in various industries.