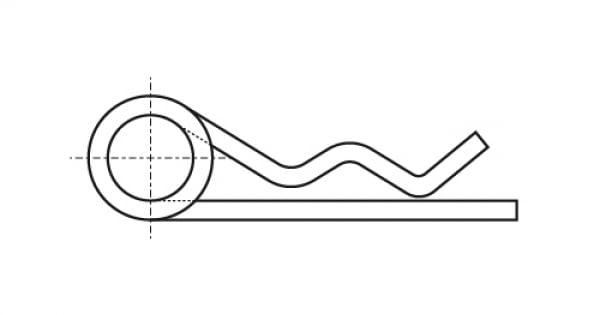

Din 11024 spring needle cotter pin is a fastener that is a metal rod of semicircular cross-section bent in half, with an eyelet formed at the bend. The straight part of this part fits into a hole prepared for it in advance, and the bent part is snapped into place in several places.

Fastening group DIN 11024

DIN 11024 is primarily made of stainless steel and belongs to the stainless steel fastener group.

Materials used to manufacture the DIN 11024 cotter pin

- Steel, which can be optionally coated with zinc.

- Stainless steel, steel grades A2 and A4. This material does not require additional coating.

Areas of application of the D-shaped cotter pin

Such cotter pins are used in mechanical engineering as a more reliable way to fix nut connections. Its main task is to prevent self-tightening of fastening nuts in the assembly of various components.

The scope of application also directly depends on the material of manufacture and coating of the cotter pin:

- Zinc-coated steel is less susceptible to corrosion if DIN 11024 is to be used in aggressive environments.

- Stainless steel. The steel grade A2 allows DIN 11024 to be used at high temperature extremes and in aggressive and humid environments.