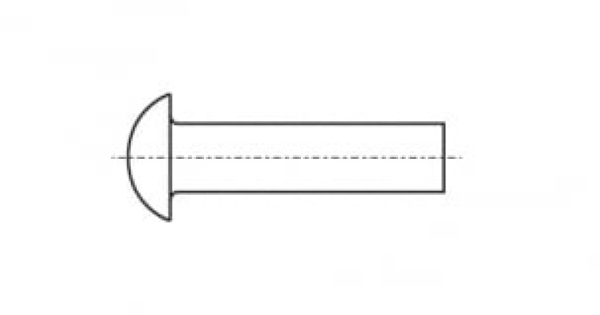

DIN 124 is a hammer rivet, one of the oldest types of fasteners. It is a simple and versatile fastener that is used to create reliable, high-strength and long-term permanent connections of two or more structural elements made of different materials. Connections made with this fastener are resistant to static, dynamic, shock, vibration loads, etc.

Fastening group DIN 124

Depending on the material of manufacture, DIN 124 rivets are divided into groups:

- Brass fasteners - fasteners made of brass

- Stainless steel fasteners - fasteners made of stainless steel grades A2 and A4

- Copper fastener - made of copper

- Aluminum fastener - made of aluminum

Materials for the manufacture of DIN 124 rivets

DIN 124 rivets are available in a variety of materials:

- Steel, which can optionally be coated with zinc

- Stainless steel grades A2 and A4

- Brass

- Copper

- Aluminum

Areas of application for DIN 124 rivets

These products are used in mechanical engineering, construction, instrumentation, and the aerospace industry. The purpose of the rivet is to connect sheet materials in a permanent manner. To install the product, it is necessary to drill a through hole in the elements to be joined, the diameter of which is 0.1 mm larger than the diameter of the rivet leg.