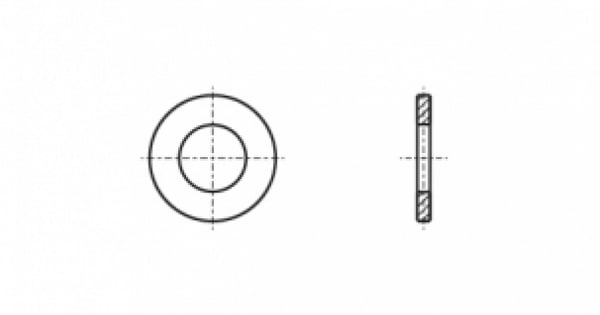

The DIN 125 flat washer is used in combination with nuts to complete bolts, screws and studs to create reliable detachable threaded connections. Din 125 is placed under the bolt head to reduce the pressure on the fastener and increase the bearing area of the fastener itself. This prevents surface deformation, increases the attachment area, holds the element on brittle substrate materials and prevents the fastener from loosening.

DIN 125 fastener group

Depending on the material of manufacture, din 125 flat washers are divided into different fastening groups:

- High-strength fastener

- Brass fastener

- Stainless steel fastener

- Polyamide fastener

- Copper fastener

- Aluminum fastener

Materials for the manufacture of washers

Material of the washer DIN 125:

- Steel

- Brass

- Polyamide

- Copper

- Aluminum

- Stainless steel A2, A4, A5

Where and how DIN 125 flat washers are used

DIN 125 is a washer that is required in all structures, no matter what materials the structure is made of: wood, metal or any other. The application of this washer rather depends on the environment in which it will be used.

- Galvanized steel is a good protection against corrosion if the fastener is to be used in an aggressive environment.

- Brass is used if the system is subjected to frequent dynamic, vibration loads.

- Stainless steel allows the fasteners to be used at significant temperature changes and in aggressive and humid environments.

- Polyamide hardware withstands mechanical shocks, does not crack or break at the permissible load factor.