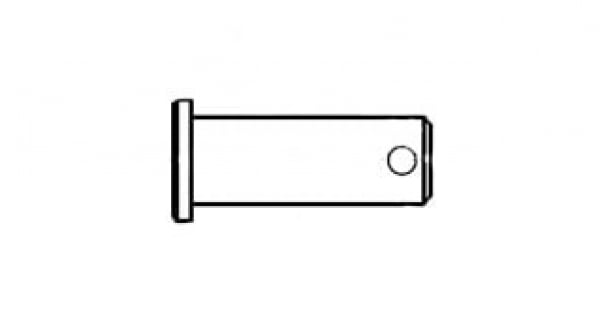

A DIN 1434 B cylindrical pin with a hole is a standard fastening element used to connect machine parts and mechanisms. It has a cylindrical shape with a central hole, allowing it to be installed using other fasteners such as split pins or retaining rings. This type of pin provides a secure connection of parts, preventing their axial movement.

Dimensions of DIN 1434 B

The dimensions of a DIN 1434 B pin are standardized and determined by the pin diameter, its length, and the hole diameter. The exact dimensions depend on the specific application and are specified in the DIN 1434 B standard.

Strength Class of DIN 1434 B

The strength class of a pin indicates its ability to withstand certain loads without failure. For DIN 1434 B pins, strength classes are typically used that correspond to the material from which they are made.

Fastening Group of DIN 1434 B

The DIN 1434 B pin belongs to the group of positioning fasteners. It is used to fix parts in a specific position and prevent their rotation.

Materials for Manufacturing DIN 1434 B

The following materials are commonly used to manufacture DIN 1434 B pins:

- Steel: Provides high strength and hardness but can be susceptible to corrosion.

- Stainless steel: Has high corrosion resistance and is used in conditions of high humidity or aggressive environments.

- Brass: Provides good corrosion resistance and easy machinability.

Applications of DIN 1434 B

DIN 1434 B pins are widely used in various industries:

- Mechanical engineering: for fixing machine parts and mechanisms.

- Instrument making: for assembling instruments and devices.

- Automotive industry: for fastening automotive parts.

- Construction: for connecting metal structures.

Advantages of using DIN 1434 B pins:

- Easy installation: Pins are easy to install and remove.

- Reliability: Provide a strong and reliable connection of parts.

- Durability: Have a long service life.

- Versatility: Can be used in various operating conditions.

The DIN 1434 B cylindrical pin with a hole is a universal and reliable fastening element, widely used in various industries. Due to its technical characteristics, it provides a strong and reliable connection of parts, making it indispensable in many manufacturing processes.