Technical Characteristics of DIN 1444 B

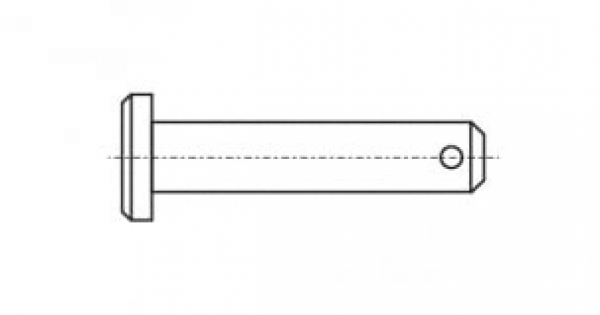

A DIN 1444 B low-head pin with a hole is a specialized type of fastener used to connect machine parts and mechanisms. The primary difference between this pin and a standard cylindrical pin is the presence of a low head, which limits the height of the connection. This allows the pin to be used in confined spaces. The hole in the head enables installation using other fasteners such as split pins or retaining rings, ensuring a secure fixation.

Dimensions of DIN 1444 B Low-Head Pin with Hole

The dimensions of a DIN 1444 B pin are standardized and determined by the pin diameter, its length, hole diameter, and head height. The exact dimensions depend on the specific application and are specified in the DIN 1444 B standard.

Strength Class of DIN 1444 B

The strength class of a pin indicates its ability to withstand certain loads without failure. For DIN 1444 B pins, strength classes are typically used that correspond to the material from which they are made. The choice of strength class depends on operating conditions such as load, vibration, and temperature.

Fastening Group of DIN 1444 B Low-Head Pin with Hole

The DIN 1444 B pin belongs to the group of positioning fasteners. It is used to fix parts in a specific position and prevent their rotation. The low head allows this pin to be used in narrow gaps where the application of a standard cylindrical pin is difficult.

Materials for Manufacturing DIN 1444 B

The following materials are commonly used to manufacture DIN 1444 B pins:

- Steel: Provides high strength and hardness but can be susceptible to corrosion.

- Stainless steel: Has high corrosion resistance and is used in conditions of high humidity or aggressive environments.

- Brass: Provides good corrosion resistance and easy machinability.

Applications of DIN 1444 B Low-Head Pin with Hole

DIN 1444 B pins are widely used in various industries:

- Mechanical engineering: for fixing machine parts and mechanisms in confined spaces.

- Instrument making: for assembling instruments and devices with limited height.

- Automotive industry: for fastening automotive parts in narrow spaces.

- Electrical engineering: for fastening electrical components.

Advantages of using DIN 1444 B pins:

- Compactness: The low head allows the pin to be used in confined spaces.

- Reliability: Provides a strong and reliable connection of parts.

- Versatility: Can be used in various operating conditions.

- Durability: Has a long service life.

The DIN 1444 B low-head pin with a hole is a versatile and reliable fastening element, used in various industries where connection of parts in confined spaces is required. Due to its technical characteristics, it provides a strong and reliable connection of parts, making it indispensable in many manufacturing processes.