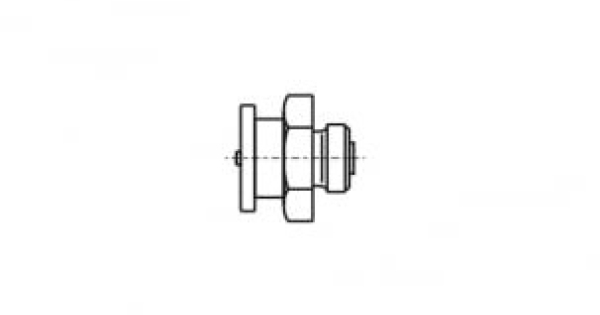

The DIN 3404 standard describes bayonet-lock grease fittings for use in industrial lubrication systems. The grease fittings according to this standard are circular in shape and consist of a body, a cover and a clamping pin. Grease fittings in accordance with DIN 3404 are commonly used in hydraulic and pneumatic systems, as well as in the lubrication of machinery and equipment. They are installed on components where it is necessary to ensure effective lubrication and provide easy access to the oil for oil changes. The main advantages of using oil fittings in accordance with DIN 3404 are that they provide reliable lubrication of moving parts and prevent oil leakage. They also provide easy installation and convenient access to the oil for oil changes and maintenance.

DIN 3404 mounting group

The DIN 3404 grease fittings are divided into groups:

- High-strength fasteners

- Stainless steel fasteners

Materials for the manufacture of DIN 3404 grease fittings

DIN 3404 grease fittings are made of the following materials:

- Steel, which can be optionally coated with zinc. Zinc (Plated) protects against corrosion if the fastener is to be used in aggressive environments.

- Stainless steel grades A1 and A4. Stainless steel allows the fasteners to be used at significant temperature fluctuations and in aggressive and humid environments.

- Brass. Brass fasteners are used if the system is subjected to frequent dynamic, vibration and cyclic loads.

Areas of application for DIN 3404 grease nipples

Grease fittings in accordance with DIN 3404 are commonly used in industrial lubrication systems, such as hydraulic and pneumatic systems, machinery and equipment, where it is necessary to ensure effective lubrication of moving parts and prevent oil leakage. These grease guns are typically installed on units where reliable lubrication of moving parts is required, such as bearings, gearboxes, transmissions, and other mechanisms. They are also used in lubrication systems of machinery and equipment where constant monitoring of the oil level is required. The main advantages of using oil lube boxes according to DIN 3404 are that they provide reliable lubrication of moving parts and prevent oil leakage. They also provide easy installation and convenient access to the oil for oil changes and maintenance. In general, oil lube boxes according to DIN 3404 are widely used in various industries and machine building, where reliable lubrication is an important condition for the smooth operation of mechanisms and systems.