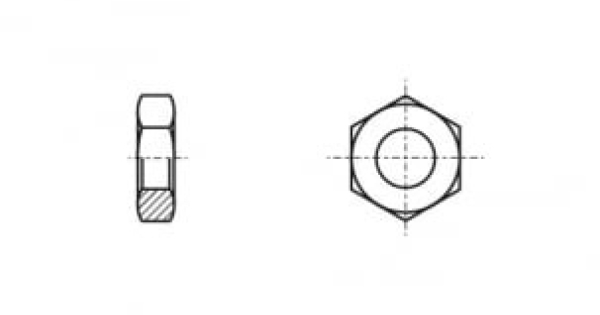

DIN 439 Hexagonal low nut is a fastener with a thread that prevents the self-detachment of connected fasteners of increased height or standard height. The main functional feature of the product is its ability to reduce the installation space. Such fasteners are used in cases where it is necessary to ensure the safety of the connection under high loads.

Strength class DIN 439

DIN 439 nuts are made of steel of strength classes 4 and 5. The strength class of a DIN 439 nut is the maximum applied force at which the nut begins to fracture.

DIN 439 fastening group

Depending on the material of manufacture, DIN 439 nuts are divided into groups:

- Stainless steel fasteners

- Brass fasteners

Materials for the manufacture of DIN 439 nuts

DIN 439 nuts are made from a variety of materials:

- Steel, which can be additionally coated with zinc, yellow zinc, and zinc plated

- Brass. Brass nuts are used when the system is subjected to frequent dynamic, vibration, and cyclic loads.

- Stainless steel grades A2 and A4. Allows the use of bolts at significant temperature changes and in aggressive and humid environments.

Areas of application for DIN 439 nuts

DIN 439 is used in shipbuilding, mechanical engineering, instrumentation, and furniture production together with nuts and bolts of the corresponding threaded connection.

The DIN 439 nut prevents the threaded connection from loosening; in this case, the nut is used only in conjunction with a standard nut, the counter-locking is applied with two tools, and the nuts are tightened to meet each other.

Adapted for use in tight spaces, but due to its height, the nut cannot be used with standard tightening torques.