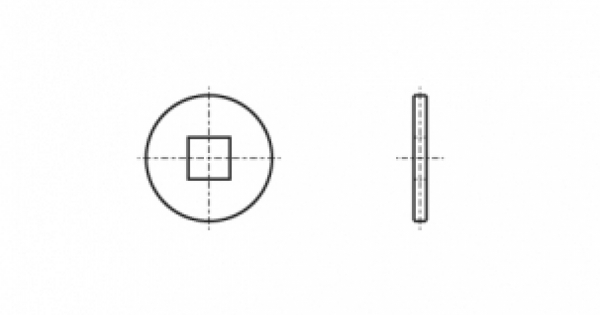

DIN 440V is a standard that defines the technical characteristics of a special type of washer that has larger dimensions compared to standard washers. This type of fastener is widely used in various industries due to its ability to distribute the load over a larger area and provide a more reliable connection.

Technical characteristics of DIN 440V

DIN 440V washers have a number of distinctive features that set them apart from standard washers:

- Increased dimensions: They have a larger outer diameter and thickness, allowing the load to be distributed over a larger area and reducing the pressure on the fastener.

- Square hole: They usually have a square hole for the bolt or nut head, which ensures a more secure fastening.

- High strength: They are made of high-quality materials, ensuring durability and resistance to loads.

- Precise dimensions: They comply with the DIN 440V standard, guaranteeing compatibility with other fasteners.

Dimensions of DIN 440V Enlarged Washer

The dimensions of DIN 440V washers are standardized and determined by the outer diameter, inner diameter (for the bolt or nut head), and thickness. The range of sizes is quite wide, allowing you to select a washer for any need.

Strength class of DIN 440V Enlarged Washer

The strength class of DIN 440V washers indicates their ability to withstand specific loads. The choice of strength class depends on the material from which the washer is made and the operating conditions. Most often, washers with a strength class that matches the material of the fastener are used.

Fastener group DIN 440V

DIN 440V washers belong to the group of fasteners used to connect various parts and materials. They are used in pairs with bolts or nuts to distribute the load and prevent surface damage.

Materials for manufacturing DIN 440V

DIN 440V washers are most often made of steel, which provides high strength and durability. However, depending on the operating conditions, other materials can be used, such as:

- Stainless steel: For use in aggressive environments or where corrosion resistance is important.

- Brass: Provides good corrosion resistance and has a high decorative value.

- Aluminum: A lightweight and corrosion-resistant material.

Application of DIN 440V

DIN 440V washers are widely used in various industries and manufacturing. They are used for:

- Increasing the bearing area: To prevent bolts and nuts from turning and to distribute the load over a larger area.

- Surface protection: To protect the surface from damage that may occur when tightening fasteners.

- Leveling surfaces: To compensate for surface irregularities and ensure a more reliable connection.

Advantages of using DIN 440V washers:

- Increased joint strength: Provide a more secure fastening.

- Protection against damage: Prevent surface damage.

- Leveling surfaces: Ensure a more even load distribution.

- Versatility: Can be used with various materials and types of fasteners.

Selection of DIN 440V washers

When selecting DIN 440V washers, the following factors should be considered:

- Material being joined.

- Material thickness.

- Expected load.

- Operating conditions (temperature, humidity).

- Washer material.

- Dimensions of the bolt or nut.

The correct choice of DIN 440V washers will ensure the reliability and durability of any fastening.