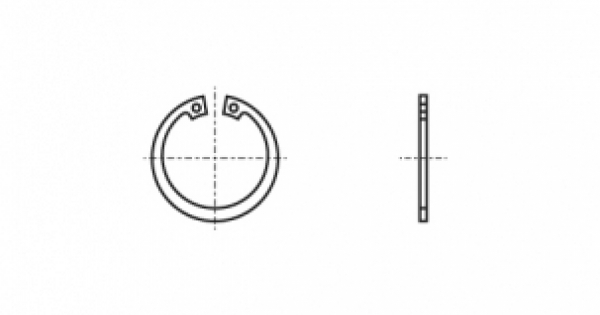

A circlip according to DIN 472 is an eccentric fastener that is used on a shaft or in a bore. Visually, this part is a ring with free edges on which holes are placed for easy fixation inside the hole.

It prevents spontaneous displacement of the mechanism elements relative to each other, which is especially important some time after installation. This increases the reliability of the structure.

DIN 472 fastening group

DIN 472 is primarily made of stainless steel and belongs to the stainless steel fastener group.

Materials of manufacture:

The DIN 472 snap ring is primarily made of:

- Steel, which can optionally be coated with zinc plating.

- Stainless steel A2, as well as 1.4532 (austenitic). This material does not require any additional treatments.

Selection of the locking inner ring

The standard of the ring should be taken into account. If we compare DIN 472 with analogs, it is thicker.

Its material should be selected taking into account the load and the environment in which it will be used.

Read more about the dimensions in din 472 pdf.

Application of the DIN 472 circlip

The grooves for din 472 circlips are located in the housing, behind the seating surface of rolling bearings and other parts, so that the protruding part of the circlip fixes the part in the mounting location.

Snap rings are used in almost all areas where housing structures with shafts, bearings and other parts are used.

Speaking specifically about the areas of application, snap rings are most popular in:

- Automotive industry

- Machine tool building

- Mechanical engineering

Special tools are used to assemble and disassemble this fastener. However, circlips with small diameters can be installed with a standard flathead screwdriver.

The scope of DIN 472 also directly depends on the material of the fastener:

- Zinc-coated steel is less susceptible to corrosion when DIN 472 is used in aggressive environments.

- Stainless steel.The steel grade A2 allows DIN 472 to be used at high temperature extremes and in aggressive and humid environments. This material does not require a coating.