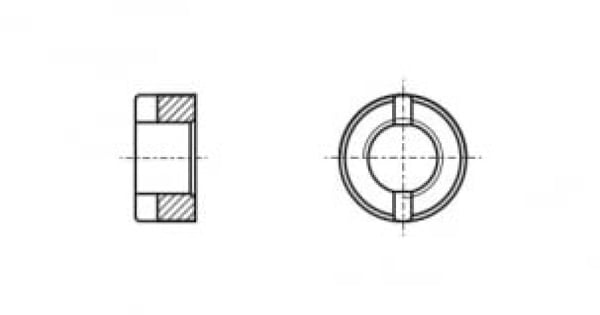

DIN 546 A spline nut is a nut used to fix coaxial parts on shafts, such as bearings, bushings, ball bearings and other rotating parts. Usually they are lower and smaller in external parameters than standard hex nuts, but they are often used on large shafts, so a design was invented in which they can be tightened with a special wrench that is smaller than a regular open-end wrench of the corresponding nut diameter. The wrench hooks onto one of the splines of the nut with a special tooth and, bending around its body, rests against it, making it possible to apply force when turning it.

DIN 546 fastening group

Depending on the material of manufacture, DIN 546 nuts are divided into groups:

- Stainless steel fasteners - fasteners made of stainless steel

- Brass fasteners - fasteners made of brass

Materials for the manufacture of DIN 546 nuts

DIN 546 nuts are made of the following materials:

- Steel, which can optionally be coated with zinc. Zinc protects against corrosion if the fastener is to be used in aggressive environments.

- Stainless steel grades A1 and A4. Allows the use of bolts at significant temperature changes and in aggressive and humid environments.

- Brass. Brass nuts are used when the system is subjected to frequent dynamic, vibration and cyclic loads.

Areas of application for DIN 546 nuts

DIN 546 nuts are widely used in the machine-building industry. They are used for the needs of the automotive industry, assembly of various parts of components and assemblies in machine tool building, instrumentation, etc. Their high strength and increased corrosion resistance extend the possibilities of their use as special fasteners, which can be used where standard hexagonal nuts cannot be used.