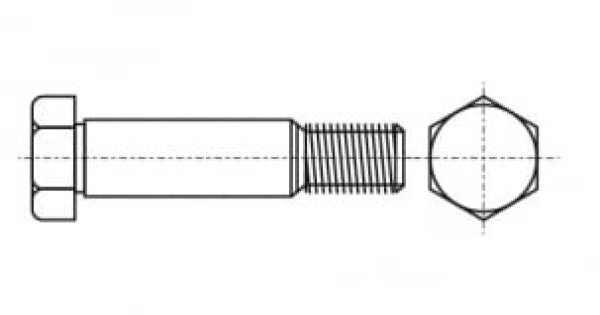

DIN 610 socket bolt is a bolt of various lengths with a reduced hexagonal head and partial thread (the thread is shorter than that of DIN 609). The diameter of the threaded part of the body is smaller than the solid part, which allows to increase the strength of the fastener several times. This goal is also facilitated by the high precision of hole preparation, as evidenced by the word “pilot” in the bolt marking. During installation, it must fit snugly into the channel. Despite having a hexagonal wrench head, the DIN 610 bolt is additionally supplied with a nut and washer of the appropriate size.

Strength class DIN 610

The strength class of a Din 610 bolt is the maximum applied force at which the bolt begins to fracture. Din 610 bolts are available in strength classes 8.8 and 10.9. From strength class 8.8, the bolt is considered high-strength. High-strength Din 610 should be purchased only from trusted suppliers. It is made of alloy steel and such bolts are used for critical projects where, in addition to high loads and static loads, the din 610 bolt is subjected to constant vibration. Such bolts will be especially relevant in bridge construction, instrumentation, and in structures that are located near objects subject to vibration.

DIN 610 fastening group

DIN 610 bolts belong to the high-strength fasteners group.

Materials for the manufacture of DIN 610 bolts

DIN 610 bolts are made of high-strength structural alloy steel. The high strength class allows the bolts to be used in highly loaded connections.

Areas of application for DIN 610 bolts

The DIN 610 bolt is used for connecting and fastening parts and structures in construction and mechanical engineering for installation in a precisely machined hole with a clearance-free fit.