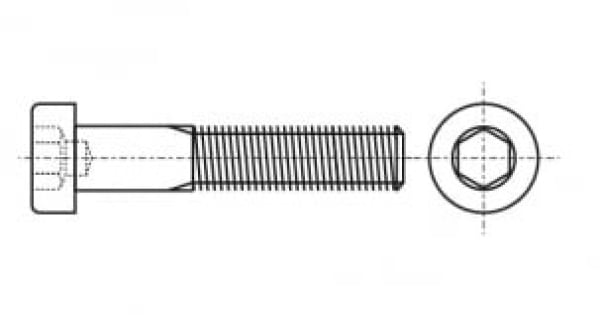

DIN 6912 is a bolt with a cylindrical head and an internal hexagon. A cylindrical head bolt is a fastener consisting of a metal stud with an incomplete metric thread and a cylindrical head with an INBUS (hexagonal) slot.

Strength class DIN 6912

The strength class of a DIN 6912 bolt is the maximum applied force at which the bolt begins to fracture. DIN 6912 bolts are manufactured in strength classes from 8.8 to 10.9. From strength class 8.8, the bolt is considered high-strength. High-strength DIN 6912 should be purchased only from trusted suppliers. It is made of alloy steel and such bolts are used for critical projects where, in addition to high loads and static loads, the DIN 6912 bolt is subjected to constant vibration. Such bolts will be especially relevant in bridge construction, instrumentation, and in structures that are located near objects subject to vibration.

Fastening group DIN 6912

Depending on the material of manufacture, DIN 6912 bolts are divided into groups:

- High-strength fasteners - bolts are made of steel with a strength class of 8.8 or higher.

- Stainless fasteners - fasteners made of stainless steel.

Materials for the manufacture of DIN 6912 bolts

DIN 6912 bolts are available in the following materials:

- High-strength structural alloy steel. The high strength class allows the bolts to be used in highly loaded connections. Which can be additionally coated with zinc and yellow zinc.

- Stainless steel grades A2 and A4. Allows the use of fasteners at significant temperature changes and in aggressive and humid environments.

Areas of application for DIN 6912 bolts

The screws are used in aerospace construction, machine building and instrumentation. To install the element, it is necessary to prepare the thread. A strong fixation is ensured by a nut or washer of the specified technical parameters.