The ease of assembly and disassembly of products connected by high-strength structural fasteners is ensured by the use of bolts, nuts and washers of the required strength class. It is simplicity and versatility that have allowed high-strength structural fasteners to find their application in a wide range of fastening of massive metal, wooden and other parts. The use of a complete set of structural fasteners (high-strength bolt, nut and two washers) makes it possible to increase the stability of the connection: strength will be achieved due to the friction force between the connected planes. To ensure that the structural fastener meets the stated strength requirement, the connection must be able to withstand frictional forces rather than shear forces (bolt shear). To achieve this, ensure that the bolts are tightened securely and that the surfaces to be joined by the structural fastener are prepared in advance.

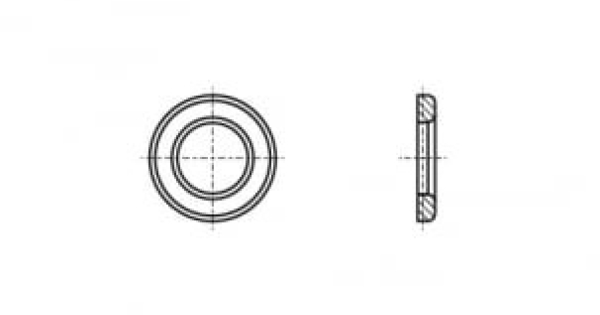

Strength class DIN 6916

Structural fasteners according to DIN 6916 are made of low-carbon alloy steel. The strength class of such washers is 300 HV.

DIN 6916 fastener group

Structural fasteners to DIN 6916 are made of low-carbon alloy steel and belong to the high-strength fastener group.

Materials for the manufacture of DIN 6916 washers

Structural fasteners according to DIN 6916 are made of low-carbon alloy steel, which can be additionally hot-dip galvanized. Hot-dip galvanizing is resistant to atmospheric corrosion.

Areas of application for washers DIN 6916

Structural fasteners with high-strength bolts, nuts and washers are used in railway construction, bridge construction, mechanical engineering, industrial production, construction of high-rise metal objects for sports, commercial and industrial purposes, etc.