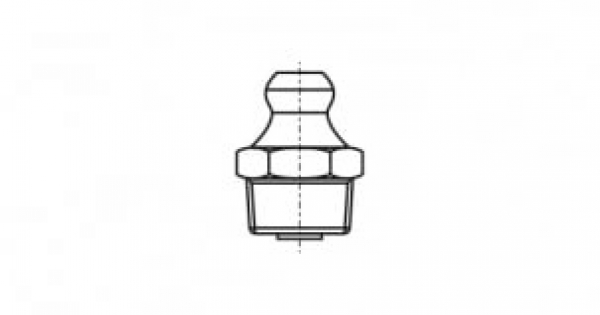

DIN 71412 A straight pressurized oiler 180 is a specialized type of fastener designed to lubricate machine parts and mechanisms. It has a cylindrical shape with an opening for supplying lubricant and a thread for mounting. The number 180 in the marking indicates its length in millimeters.

Technical Characteristics of DIN 71412 A

DIN 71412 A oilers are manufactured according to the international standard DIN 71412, which defines their geometric dimensions, materials, and other technical parameters. The main characteristics are:

- Body material: Usually made of brass or steel, ensuring strength and corrosion resistance.

- Seal material: A special seal is used, which ensures tightness and prevents lubricant leakage.

- Thread type: Depending on the application, it can be a metric or inch thread.

- Operating pressure: Determines the maximum pressure that the oiler can withstand during lubricant supply.

- Temperature range: Indicates the temperature range at which the oiler can operate effectively.

Dimensions of DIN 71412 A Straight Pressurized Oiler 180

The dimensions of the oiler are determined by the thread diameter, body length, and diameter of the lubricant supply hole. The DIN 71412 standard sets precise tolerances for dimensions, ensuring compatibility of oilers from different manufacturers.

Strength Class of DIN 71412 A

The concept of "strength class" does not apply to oilers, as they are not subjected to the same loads as bolts or nuts. Their strength is determined by the body material and the quality of the seal.

Fastener Group DIN 71412 A Straight Pressurized Oiler 180

The DIN 71412 A oiler belongs to the group of lubricating fittings. Its main task is to ensure the supply of lubricant to the required points of the mechanism.

Materials of Manufacture DIN 71412 A

- Brass: Provides good corrosion resistance and wear resistance, which is important for operation in aggressive environments.

- Steel: Provides high strength and rigidity, allowing it to withstand significant loads.

Application of DIN 71412 A Straight Pressurized Oiler 180

DIN 71412 A oilers are widely used in various industries:

- Mechanical engineering: For lubricating bearings, gears, guides, and other moving parts of machines.

- Automotive industry: For lubricating joints, wheel bearings, steering mechanisms.

- Metalworking: For lubricating machines, tools, and mechanisms.

- Construction: For lubricating construction equipment.

Advantages of using DIN 71412 A oilers:

- Reliability: Ensure tightness and prevent lubricant leakage.

- Durability: Made from durable materials, ensuring a long service life.

- Ease of use: Simple design allows for easy installation and maintenance of the oiler.

- Versatility: Can be used with various types of lubricants.

The DIN 71412 A oiler is an indispensable element for ensuring the efficient operation of machines and mechanisms. Due to its design features and high quality materials, it provides reliable lubricant supply and extends the service life of equipment.