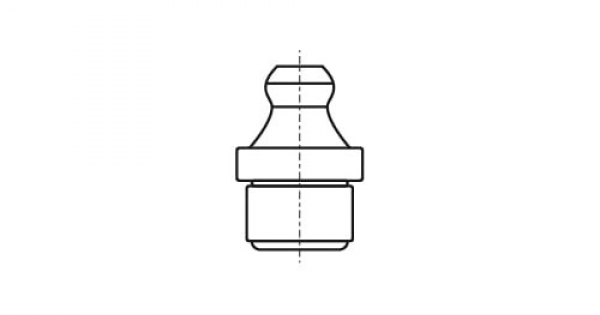

A DIN 71412 oiler is a specialized fastener designed for the automatic lubrication of machine and equipment parts. It consists of a metal housing with a grease reservoir and a sharp tip that, when screwed in, penetrates the component and provides a supply of grease.

Various modifications of DIN 71412 oilers differ in the angle of inclination of the tip, the material of manufacture, and other characteristics, allowing you to choose the optimal option for specific operating conditions.

Operating Principle

The operating principle of the oiler is quite simple. The grease is supplied under pressure from the reservoir through a hole in the tip to the lubricated surface. The angle of inclination of the tip allows the grease to be directed in the desired direction.

Materials and Construction

DIN 71412 oilers are usually made of stainless steel or brass to ensure high corrosion resistance and durability. The design of the oiler includes:

- Housing

- Grease reservoir

- Tip

- Seal

Areas of Application

DIN 71412 oilers are widely used in various industries:

- Mechanical engineering: for lubricating bearings, hinges, guides, and other moving parts.

- Automotive industry: for lubricating chassis parts, steering mechanisms, and other assemblies.

- Metalworking: for lubricating tools and equipment.

DIN 71412 Oiler with Index 180

The DIN 71412 oiler with index 180 is a modification of the standard model and has a number of features. [Here you need to add detailed information about this model, if available. For example: "The DIN 71412 oiler with index 180 has a tip angle of 180 degrees, which allows parts to be lubricated from both sides simultaneously. This is especially useful for lubricating parts located in hard-to-reach places."]

Advantages of Using DIN 71412 Oilers

- Automatic lubrication: provides a continuous supply of grease.

- Reliability: made of high-quality materials and has a long service life.

- Ease of installation: easily installed anywhere.

- Grease savings: precise dosing of grease prevents its overuse.