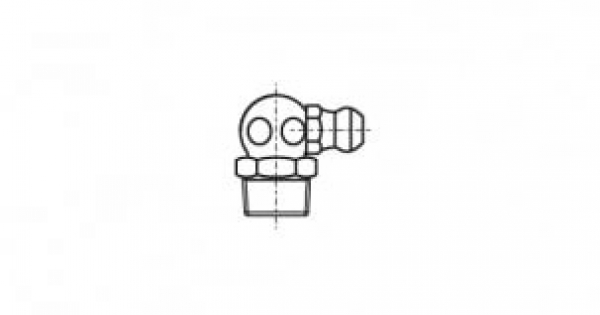

A DIN 71412 C oil press fitting is a specialized fastening element designed for efficient lubrication of machine parts and mechanisms. Its distinctive feature is a 90-degree angle, enabling vertical oil delivery. This makes it ideal for lubricating parts positioned vertically or at a right angle to the fitting's axis.

Technical Specifications of DIN 71412 C

- Material: Similar to the DIN 71412 B model, DIN 71412 C oil press fittings are typically made of stainless steel or brass, ensuring high corrosion resistance and durability.

- Dimensions: Dimensions may vary slightly from the DIN 71412 B model, but overall the same basic parameters are maintained: thread diameter, length, and oil reservoir capacity.

- Accuracy Class: Oil press fittings are manufactured with high precision, guaranteeing a reliable connection to machine parts and minimizing the risk of oil leakage.

- Operating Temperature: Typically, the operating temperature of DIN 71412 C oil press fittings is the same as that of the DIN 71412 B model, allowing for use in a wide temperature range.

Applications of DIN 71412 C

DIN 71412 C oil press fittings are widely used where vertical oil delivery is required:

- Machinery: Lubrication of vertical shafts, guides, and spindles.

- Automotive industry: Lubrication of shock absorbers, vertical joints.

- Metalworking: Lubrication of vertical presses, drilling machines.

- Construction: Lubrication of vertical lifts, conveyors.

Comparison of DIN 71412 C and DIN 71412 B

The main difference between these two models lies in the angle of inclination. The DIN 71412 C has a 90-degree angle, allowing for vertical lubrication, while the DIN 71412 B has a 45-degree angle and is used for more universal lubrication.

Advantages of using DIN 71412 C oil press fittings

- Precise vertical lubrication: Ensures efficient lubrication of vertically positioned parts.

- Easy installation: Easily installed in pre-drilled holes.

- Durability: Made of high-quality materials, resistant to corrosion and wear.

- Versatility: Can be used in various industries.