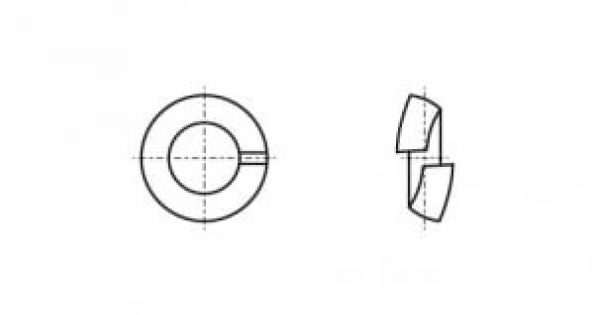

A grover (or split washer) is a small, metal ring-shaped component with a slit. It is used to prevent nuts and bolts from loosening. It creates additional friction between the threaded connection, preventing it from becoming loose due to vibrations or dynamic loads.

Construction and Materials

Grovers are made from various materials, most commonly steel, stainless steel, or brass. The shape and size of grovers can vary depending on the diameter of the bolt or nut, and the operating conditions.

How it works

When tightening a nut or bolt, the grover is stretched and wedges into the groove under the head. During operation, the grover maintains tension, preventing loosening.

Advantages of using grovers

- Reliability: Grovers significantly increase the reliability of threaded connections, especially under vibration conditions.

- Ease of use: No special tools are required to install a grover.

- Availability: Grovers are inexpensive and widely available.

- Versatility: They can be used with various types of threaded connections.

Applications

Grovers are widely used in mechanical engineering, automotive, construction, and other industries where reliable fastening of threaded connections is required.

DIN 74361 C Standard

The DIN 74361 C standard likely defines the specific technical characteristics of the grover, such as dimensions, tolerances, materials, and quality requirements. For more detailed information on this standard, it is recommended to consult the appropriate technical documentation.