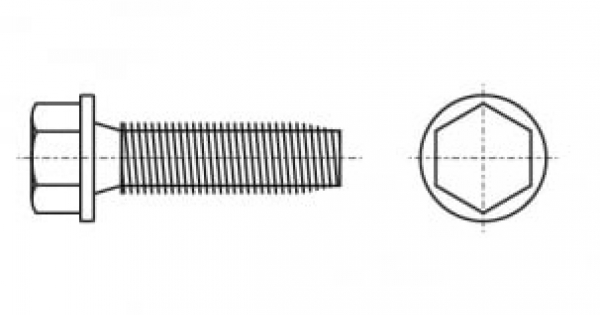

The DIN 7500 D screw is a versatile fastening element that combines the functions of a screw and a press-in washer. Its design includes a hexagonal head for tightening with a wrench, a threaded part for creating a connection, and a press-in washer that provides additional pressure on the part and prevents rotation.

Key Features:

- Hexagonal head: Ensures secure tightening with a hex key.

- Press-in washer: The built-in press-in washer, with or without threads, distributes the load over a larger area, preventing rotation and material deformation.

- Thread: Metric thread is typically used, but other types may be possible depending on specific requirements.

- Material: Usually made of steel, but can be made of stainless steel or other materials, depending on operating conditions.

- Coating: To protect against corrosion and improve appearance, various coatings such as zinc, cadmium or oxidation are often used.

DIN 7500 D Dimensions

The dimensions of DIN 7500 D screws are regulated by the international standard DIN 7500 D. They include thread diameter, thread length, smooth length, head dimensions, hexagon, and press-in washer. The specific dimensions depend on the purpose of the screw and are selected according to technical requirements.

Strength Class of DIN 7500 D

The strength class of DIN 7500 D screws is determined by its ability to withstand various types of loads. The most common strength classes are:

- 8.8: Used for general construction and in mechanical engineering.

- 10.9: Used for connections subjected to high loads, such as in structures operating under dynamic conditions.

- 12.9: Used for especially critical connections requiring maximum strength and reliability.

Fastener Group DIN 7500 D

DIN 7500 D screws belong to the group of fasteners that provide a non-separable connection of parts. They are used independently, without additional nuts, thanks to the presence of a press-in washer.

Materials for the Manufacture of DIN 7500 D

Carbon steel with alloying additives that increase strength and corrosion resistance is most often used for the manufacture of DIN 7500 D screws. Stainless steel and other special alloys can also be used for work in aggressive environments.

Scope of Application of DIN 7500 D

DIN 7500 D screws are widely used in various industries:

- Mechanical engineering: for connecting thin sheets of metal, plastic parts, and other materials.

- Automotive industry: for fastening interior elements, upholstery, and other parts.

- Furniture industry: for connecting wooden and metal elements of furniture.

- Electrical engineering: for fastening electrical components.

Advantages of using DIN 7500 D screws:

- Versatility: Can be used for various materials and types of connections.

- Reliability: Provides a strong and reliable connection of parts.

- Installation speed: Does not require the use of additional tools and nuts.

- Aesthetic appearance: Can be used for decorative purposes.

The use of DIN 7500 D screws allows creating strong, reliable, and durable connections, which is important for ensuring the safety and efficiency of various mechanisms and structures.