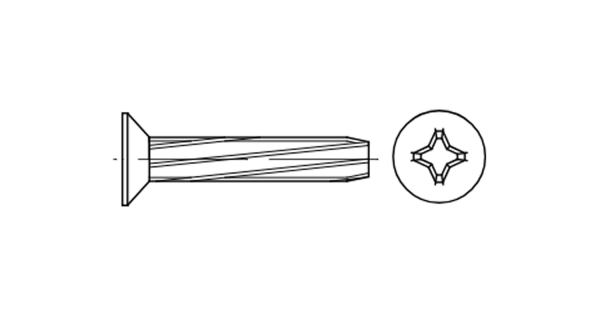

DIN 7516 D Countersunk Head Self-Tapping Screw

Technical Specifications of DIN 7516 D

DIN 7516 D is a countersunk head self-tapping screw designed for creating reliable connections in metal without pre-cutting threads. The key feature of this screw type is its ability to form a threaded connection during screwing.

Main specifications:

- Head type: Countersunk, ensuring a flush surface after installation.

- Thread type: Self-tapping, allowing thread formation without additional tools.

- Material: Carbon steel or stainless steel.

- Coating: Zinc plating, nickel plating, or phosphating for corrosion protection.

- Application: Fastening metal structures, mounting cladding panels, assembling mechanical components.

DIN 7516 D is widely used in mechanical engineering, the automotive industry, and construction due to its high strength and ease of installation.

Strength Class of DIN 7516 D Countersunk Head Self-Tapping Screw

The strength class of DIN 7516 D screws depends on the manufacturing material. The main strength options include:

- Carbon steel 4.8, 5.8, 8.8 – Standard strength for medium loads.

- Stainless steel A2, A4 – High corrosion resistance, suitable for use in humid environments.

- Zinc-coated steel – Additional corrosion protection, increasing the fastener's service life.

The choice of strength class depends on operating conditions and the required load-bearing capacity of the connection.

Fastener Group of DIN 7516 D

DIN 7516 D belongs to the group of self-tapping screws used to create threaded connections without pre-cutting threads in the material. Features of this fastener group include:

- Used for assembling metal structures without additional processing.

- High strength and resistance to vibration loads.

- Ensures uniform load distribution due to the countersunk head.

These screws are applied where quick and reliable connections are needed without using additional thread-cutting tools.

Manufacturing Materials of DIN 7516 D Countersunk Head Self-Tapping Screw

DIN 7516 D screws are made from various materials depending on the operating conditions and required strength. The main materials include:

- Carbon steel – The most common option, providing good mechanical strength.

- Stainless steel (A2, A4) – Used in humid and aggressive environments, does not require additional coating.

- Zinc-coated steel – The protective coating prevents corrosion, making the screws suitable for use in damp conditions.

The choice of material depends on the application. Carbon steel is sufficient for standard constructions, while stainless steel is recommended for aggressive environments.

Application Areas of DIN 7516 D

DIN 7516 D screws are widely used in various industries and construction due to their technical characteristics.

Main application areas:

- Automotive industry – Fastening metal parts, assembling body components and internal structures.

- Construction – Used for mounting cladding panels, joining metal structures.

- Mechanical engineering – Applied in the manufacturing of industrial equipment and machinery.

- Electronics – Used for assembling electronic device enclosures, ensuring secure fastening.

The installation of DIN 7516 D screws is carried out using a screwdriver or drill. Thanks to the self-tapping thread, the fastening process is simplified and does not require pre-drilled holes.

The application area also depends on the manufacturing material:

- Zinc-coated steel – Provides additional corrosion protection, which is crucial for use in humid and aggressive environments.

- Stainless steel A2 – Resistant to corrosion, suitable for environments with temperature fluctuations and high humidity.

Due to their technical characteristics, DIN 7516 D self-tapping screws are an effective solution for many industries and construction projects.