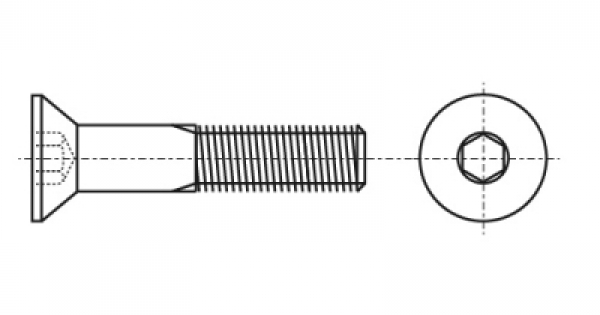

A din 7991 screw is a fastener that has a countersunk cone-shaped head with a slot for an internal hexagon or Torx and a rod with a fully metric thread. With this design, the bolt head is fully included in the plane in which it is fixed, and the slot allows for maximum tightening force without the risk of slot breakage.

Strength class DIN 7991

The strength class is the maximum applied force at which the bolt begins to fracture. DIN 7991 bolts are manufactured in various sizes from high-strength structural alloy steel with a strength class of 8.8 to 10.9, and are used for critical projects where, in addition to high loads and static loads, they are subject to high stress.

Fastening group DIN 7991

Depending on the material of manufacture, the bolt is divided into different fastening groups:

- High-strength fasteners

- Stainless steel fasteners

- Materials of manufacture

Materials of manufacture

The bolt is available in the following materials:

- Steel, which can optionally be coated with plain and plate black zinc

- Stainless steel (A2, A4) does not need to be coated

Where high strength bolts DIN 7991 are used

The din 7991 bolt has a slot that allows the use of pneumatic and power tools to install them quickly and easily. As a result, they are often used in conveyor assembly as flush-mounted fasteners for flush mounting. They are used to fasten parts in structures with high safety and aesthetic requirements. They are mainly used in the manufacturing, industrial and construction industries.

In addition, the scope of application directly depends on the material of manufacture and coating of the product:

- Galvanized steel offers good corrosion protection if the fastener is to be used in aggressive environments.

- Stainless steel allows the fasteners to be used at high temperature extremes and in aggressive and humid environments.