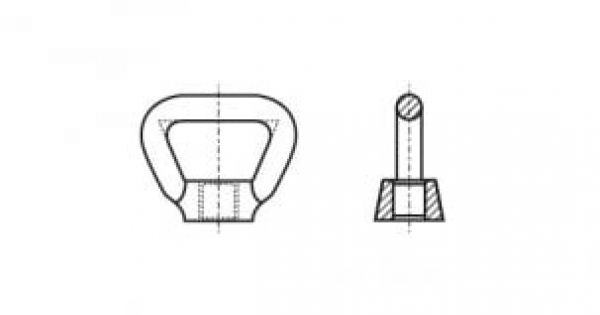

A mooring nut is a specialized type of nut designed for use in high-stress environments and exposure to corrosive substances. It's typically used to secure massive structures like mooring lines, lifting equipment, and other engineering structures.

Construction and Materials

A mooring nut has a robust construction that ensures a secure connection. It's usually made of corrosion-resistant materials such as stainless steel or special alloys. To increase strength and wear resistance, the nut may have additional elements like washers or rings.

How it Works

The working principle of a mooring nut is similar to that of a regular nut. It's screwed onto a threaded bolt, creating a strong connection. However, due to its design and materials, the mooring nut can withstand significantly higher loads and exposure to harsh environments.

Advantages of Using a Mooring Nut

- High strength: The mooring nut can withstand significant loads without deformation.

- Corrosion resistance: Thanks to the use of corrosion-resistant materials, the mooring nut can be used in aggressive environments.

- Reliability: The secure connection ensures safe operation of equipment.

- Durability: Due to its strength and wear resistance, the mooring nut has a long service life.

Applications

Mooring nuts are widely used in the marine industry, construction, energy, and other sectors where reliable connections are needed in high-stress and corrosive environments.

DIN 80704 Standard

The DIN 80704 standard likely defines the specific technical characteristics of the mooring nut, such as dimensions, tolerances, materials, and quality requirements. For more detailed information on this standard, it is recommended to consult the appropriate technical documentation.