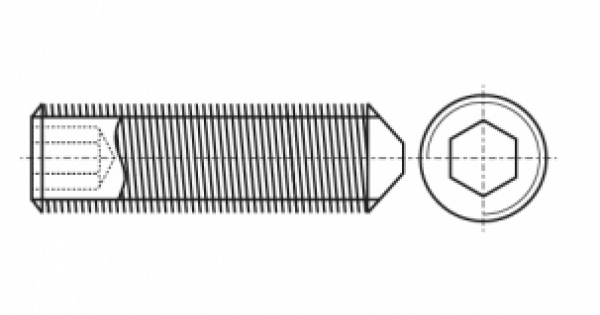

Locking screw DIN 914 with internal hexagon, threaded along the entire length and tapered end. The tapered end has a special shape that serves to fix the elements relative to each other.

Materials used to manufacture DIN 914 tapered socket head screws

The DIN 914 screw is made from a variety of materials:

- Steel, which can optionally be coated with zinc

- or DIN 914 Stainless steel A2 and A4

Area of application

The DIN 914 set screw is used whenever there is a need to fasten workpieces. Additional reliable fixation of the mutual positioning is achieved if the inner surfaces of the parts are made with projections with a corresponding recess.

This fastener is most often used in machine tools, as well as in the automotive and aircraft industries. It is used in conjunction with nuts and washers of the appropriate size (see din 914 pdf) and material.

The range of applications also depends on the material of manufacture and the coating of the product:

- Zinc coating on steel provides corrosion protection if the fastener is to be used in aggressive environments

- Stainless steel, grade A2. The material is non-toxic and corrosion-resistant, which makes it suitable for use in the food and medical industries.

- A4 is the second most popular grade; it also has similar properties to A2, but is more resistant to corrosion in aggressive environments and acids due to the addition of molybdenum.