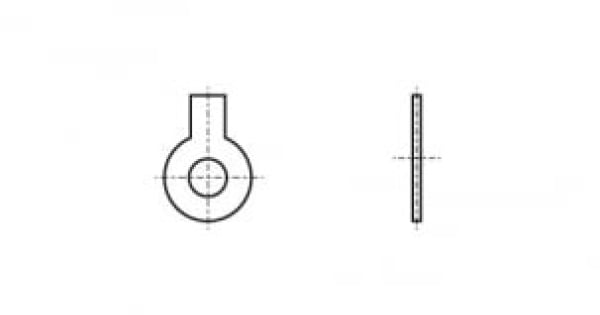

DIN 93 is a washer that prevents the threaded connection from loosening under the influence of vibrations, high loads and other factors arising during operation.

DIN 93 fastening group

DIN 93 washers are most often made of stainless steel and belong to the stainless fastener group.

Materials for the manufacture of DIN 93 washers

DIN 93 washers are made of the following materials:

- Steel, which can optionally be coated with white and hot-dip zinc. This protects the DIN 93 washer from corrosion if the fastener is to be used in aggressive environments.

- Stainless steel grades A2 and A4, this material does not require a coating.

Areas of application for DIN 93 washers

The lock washer with a foot is used to prevent self loosening of a threaded connection. The use of this type of washers is necessary when the threaded connection needs to be given additional reliability in terms of absorbing vibration or other loads, and to eliminate the effects of vibration loads and deformation external resistances that can cause loosening or loosening of the connections. DIN 93 lock washers are widely used in those areas of human activity that require meeting the most stringent requirements for fixing system elements and parts: instrumentation, automotive, mechanical engineering, machine tool, construction, and even aerospace.