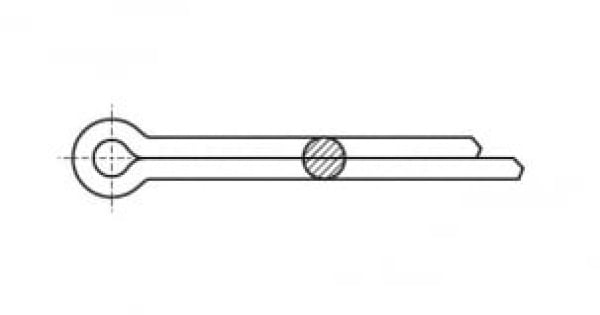

DIN 94 is the simplest cotter pin that fixes a part on shafts or threaded elements through drilled holes of the appropriate diameter, after installation in which the ends of the cotter pin are spread apart, fixing it.

DIN 94 fastening group

Depending on the material of manufacture, DIN 94 cotter pins are divided into groups:

- Cotter pins made of stainless steel belong to the stainless steel fastener group

- Those made of brass are classified as brass fasteners

- Made of copper - copper fasteners

Materials for the manufacture of DIN 94 cotter pins

DIN 94 cotter pins are available in a variety of materials:

- Stainless steel. Steel grades A2 and A4 allow the fasteners to be used at high temperature extremes and in aggressive and humid environments.

- The steel is coated with zinc. Zinc (Plated) protects against corrosion if you plan to use the fasteners in aggressive environments.

- Brass. Brass fasteners are used if the system is subjected to frequent dynamic, vibration and cyclic loads.

Application range of DIN 94 cotter pins

Used as an independent element, and in combination with a washer or a crown nut. It is used in almost all industries.

The cotter pin is one of the most common parts and is used in mechanical engineering, automotive, electrical engineering, and instrumentation. The part belongs to the group of locking products.