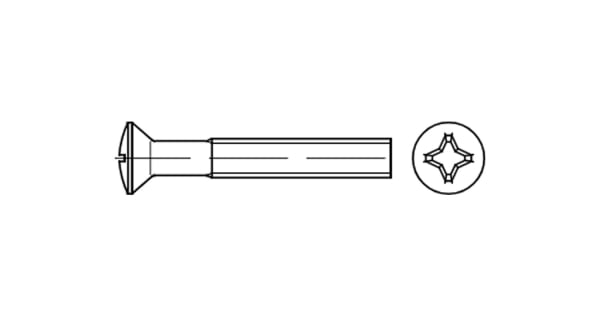

As a rule, to connect several structural parts, stainless fasteners with semi-hidden heads are used from the outside. Thanks to their technical characteristics and design features, these screws create a reliable, strong connection of parts, and also preserve the aesthetic appearance of the structure.

Strength class DIN 966

The DIN 966 screw strength class is the maximum applied force at which the screw begins to break. DIN 966 screws are manufactured in strength class 4.8.

Fastening group DIN 966

DIN 966 screws are most often made of stainless steel and belong to the group of stainless fasteners.

Materials for the manufacture of DIN 966 screws

DIN 966 screws are made of the following materials:

- Steel of strength class 4.8. which is additionally covered with zinc

- A2 and A4 stainless steel, the coating material does not need

Scope of application of DIN 966 screws

The DIN 966 screw has gained wide application in the fields of industrial production:

- mechanical engineering,

- car manufacturing,

- courts,

- industrial equipment,

- mechanisms and aggregates.

An important advantage of DIN 966 screws is their practicality in aesthetic aspects. Fasteners with a hemispherical semi-concealed head do not spoil the appearance of the assembled product, and if necessary, the screw caps can be covered with decorative overlays. This made it possible to add them to the list of use in furniture production, various construction and finishing works. Universal fastening ensures a strong connection of various materials.