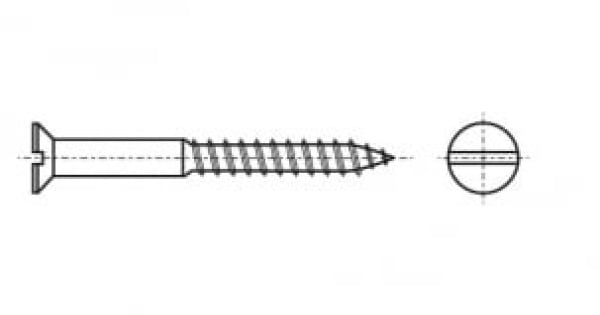

DIN 97 screws provide a secure connection between wooden parts or metal elements. They have a special thread shape that allows them to penetrate the wood without any problems and create a strong connection. These screws have a tapered head that can be sunk into the surface of the wood, which ensures an even distribution of the load on the connection element and reduces the risk of tearing the wood.

DIN 97 fastening group

Depending on the material of manufacture, DIN 97 screws are divided into groups:

- Brass fasteners

- Stainless steel fasteners

Materials for the manufacture of DIN 97 screws

DIN 97 screws are made of the following materials:

- Steel, which is additionally coated with zinc. Zinc (Plated) protects against corrosion if the fastener is to be used in aggressive environments.

- Stainless steel grades A2 and A4. This steel grade allows the fasteners to be used at high temperature extremes and in aggressive and humid environments.

- Brass. Brass screws are used if the system is subjected to frequent dynamic, vibration and cyclic loads.

Areas of application for DIN 97 screws

DIN 97 screws are commonly used in construction and carpentry to connect various wooden parts to each other or to metal elements. These screws are reliable and durable connecting elements that provide a stable connection of wooden elements without the need for additional fasteners. The application of DIN 97 screws can be quite wide, including the manufacture of furniture, wooden building structures, stairs, railings, terraces, pergolas, gazebos, frames and other wooden elements. In addition, DIN 97 screws can be used in repair work to quickly and efficiently connect wooden elements. They can also be used in the production of packaging materials and in other industries that require a reliable connection of wooden parts. Thus, DIN 97 is a fairly versatile standard that has found wide application in various industries involving the use of wooden structures and elements.