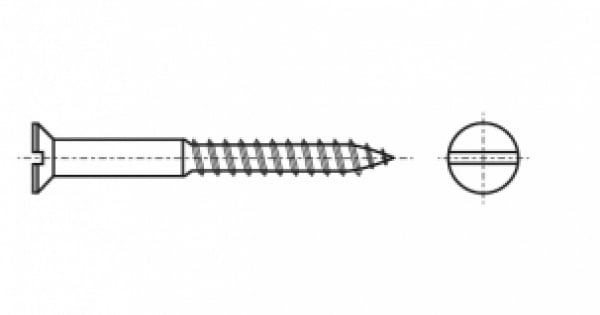

DIN 97 is a standard that defines the technical specifications for countersunk screws with a straight slot. This type of fastener is widely used in various industries and construction due to its versatility and reliability.

Technical Characteristics of DIN 97

DIN 97 screws are characterized by high manufacturing quality and meet strict standard requirements. They have a countersunk head, which allows the screw to be recessed into the material, providing a flush surface after tightening. The straight slot simplifies the tightening and loosening process using a screwdriver.

Dimensions of DIN 97 Countersunk Screw with Straight Slot

The dimensions of DIN 97 screws are standardized and determined by the thread diameter and length. The most common thread diameters range from M3 to M12, while the length can vary widely depending on the specific application.

Strength Grade of DIN 97 Countersunk Screw with Straight Slot

The strength grade of DIN 97 screws indicates their ability to withstand certain loads. The choice of strength grade depends on the material of the screw and the operating conditions. Screws with a strength grade of 4.8, 8.8, or 10.9 are most commonly used.

Fastener Group DIN 97

DIN 97 screws belong to the group of fasteners used to join various materials. They are used in combination with nuts or screwed directly into pre-drilled holes.

Materials for Manufacturing DIN 97

DIN 97 screws are most often made of steel, which provides high strength and durability. However, depending on operating conditions, other materials such as:

- Stainless steel: For use in aggressive environments or where corrosion resistance is important.

- Brass: Provides good corrosion resistance and has a high decorative value.

- Aluminum: Lightweight and corrosion-resistant material.

Application Area of DIN 97

DIN 97 screws are widely used in various industries and construction. They are used for:

- Joining wooden parts: In the furniture industry, construction.

- Assembling metal structures: In mechanical engineering, metal structures.

- Fastening plastic parts: In electronics, instrumentation.

- Automotive industry: For joining automotive parts.

Advantages of using DIN 97 screws:

- Reliability: Provides a strong and durable connection.

- Versatility: Can be used for various materials.

- Ease of installation: Easy to use thanks to the straight slot.

- Aesthetic appearance: The countersunk head provides a flush surface.

Choosing DIN 97 screws

When choosing DIN 97 screws, the following factors should be considered:

- Material to be joined.

- Material thickness.

- Expected load.

- Operating conditions (temperature, humidity).

The correct choice of DIN 97 screws will ensure the reliability and durability of any fastening.