Watch more expert videos on our YouTube channel

Expert video blog

Expert video blog

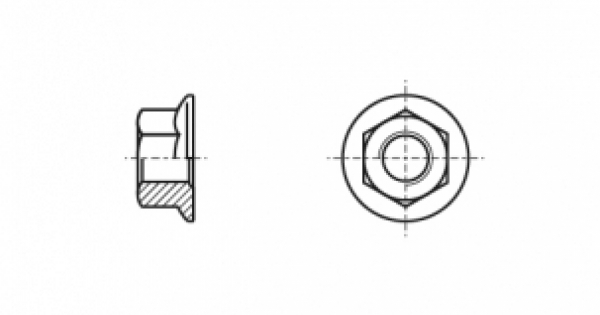

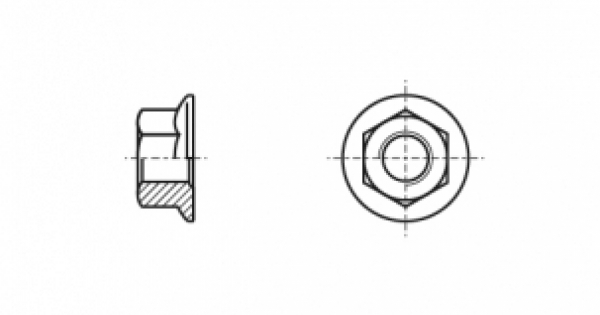

EN 1661 has a regular hexagonal shape with a threaded connection in the center; the nut has special notches on the outside that cut into the metal when tightened.

The strength class of an EN 1661 nut is the maximum applied force that causes the nut to fracture. EN 1661 nuts are manufactured in strength classes from 6 to 12. From strength class 8 onwards, the nut is considered to be high-strength.

EN 1661 is manufactured in the following materials:

DIN 6923 is used in industrial construction, machine tool and instrumentation, etc.

In addition, the range of applications directly depends on the material of manufacture and the coating of the product:

Enter your email address to follow the Dinmark news