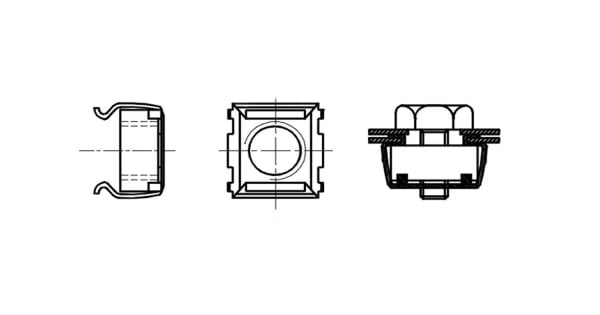

Embedded Square Nut DIN 88109

The embedded square nut DIN 88109 is a specialized fastener designed for secure installation in metal or concrete structures. It has a square shape, which ensures reliable retention in the seating location and prevents rotation during installation. It is primarily used in construction, mechanical engineering, and heavy industrial equipment.

Nuts of this standard are used to create strong, durable, and vibration-resistant connections in combination with bolts or studs. DIN 88109 regulates precise product parameters, allowing for standardized design and assembly processes.

Technical Specifications of DIN 88109

The DIN 88109 nut has the following standard technical characteristics:

-

Shape: Square with internal threading

-

Material: Structural or alloy steel

-

Coating: Most commonly electro-galvanized for corrosion protection; phosphating or black oxide coating may also be used

-

Design: Embedded form allows installation in molds or cavities without access from both sides

-

Mounting: Performed by pressing, welding, or embedding in concrete

A key feature of these nuts is the ability to pre-install them before concrete pouring or during frame assembly, ensuring stability and precision of the threaded connection.

Strength Class of Embedded Square Nut DIN 88109

DIN 88109 nuts are produced in various strength classes depending on the load they are expected to withstand. The main classes include:

-

5.6, 6.8 — For medium-load structures

-

8.8, 10.9 — For joints with high mechanical demands, including vibration loads

-

12.9 — For ultra-high strength connections in critical structures (rarely used due to stringent material and quality control requirements)

The choice of strength class depends on the operating conditions: expected load, type of structure, and safety requirements.

Fastener Group DIN 88109

DIN 88109 nuts belong to the group of embedded fasteners. Their main function is to provide a fixed threaded connection in structures where it is not possible or practical to use conventional bolt or stud assemblies requiring access from both sides.

Due to their square shape, they are securely fixed in a pre-prepared location, allowing for quick installation without the need to hold the nut from the opposite side. This is especially relevant when the structure is inaccessible after assembly.

These nuts are considered specialized components for the installation of heavy structures and are categorized under engineering or construction fasteners.

Materials for Manufacturing Embedded Square Nut DIN 88109

The primary materials used to manufacture DIN 88109 nuts include:

-

Steel (carbon or structural): Offers high strength and is suitable for most industrial applications

-

Stainless steel (A2, A4): Used in aggressive environments where high corrosion resistance is required (e.g., food processing, chemical industry, marine applications)

-

Alloy steel: Used for manufacturing high-strength nuts (e.g., strength class 10.9 and above)

-

Coating: Depending on the application, coatings may include electro-galvanizing, phosphate coating, or thermal diffusion zinc coating for enhanced corrosion resistance

Material and coating are selected based on environmental conditions, temperature fluctuations, humidity levels, and chemical exposure.

Application Areas of Washers in DIN 88109

Although the DIN 88109 standard specifically refers to nuts, washers may also be used in certain assemblies along with them. Primary application areas include:

-

Construction: Installation of metal frames, embedded elements in concrete, anchoring systems

-

Mechanical engineering: Fastening elements exposed to constant loads and vibrations

-

Heavy equipment: Installation of machines, presses, lifting systems, where secure fixation is required without rear-side access

-

Bridge construction, energy sector: Fastening of critical components that must remain stable for decades of operation

The embedded square nut DIN 88109 is a critical element for reliable fastening in conditions with limited or restricted access. Standardized specifications, high strength classes, and resistance to external influences make this type of fastener an optimal choice for a wide range of industrial and construction applications.