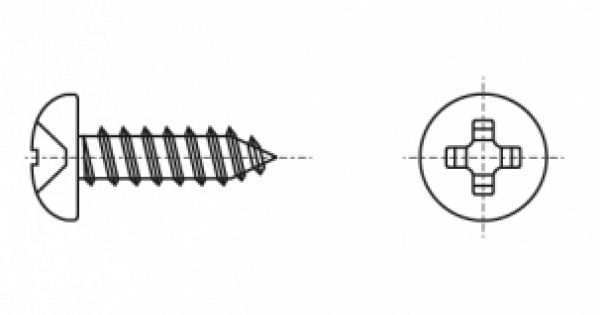

A self-tapping screw in accordance with GOST 10621-80 is a semicircular head screw with a sharp end and a slot. At one end of the rod there is a semicircular or countersunk head with a straight or cross-shaped slot (Philips, Pozidriv or Torx). On the opposite side there is a tip, which can be with a sharp end (shape C) or with a blunt end (shape F). If a semicircular head and blunt end self-tapping screw is used, it is necessary to mark and pre-drill a hole in the material before installing it. The diameter of the holes must exactly match the diameter of the metal product.

Fastening group GOST 10621-80

Basically, these screws are made of stainless steel and belong to the stainless steel fastener group.

Materials for the manufacture of GOST 10621-80 screws

GOST 10621-80 screws are manufactured in a variety of materials:

1. Steel, which can be additionally coated:

- Zinc

- Black zinc

- Black zinc with a black cloth

2. Stainless steel A2 and acid-resistant steel A4. Thanks to the alloying elements that make up the steels, self-tapping screws in accordance with GOST 10621-80 are resistant to corrosion, external weathering, sudden temperature changes, and perform well in high humidity conditions, etc. A4 grade steel products can be used in structures that come into contact with certain aggressive environments: salt water, acids and alkaline solutions.

Areas of application of GOST 10621-80

Self-tapping screws of GOST 10621-80 are a universal fastener. Their main application is fastening sheet metal or other types of steel materials to load-bearing metal and steel structures. Self-tapping screws can also be used to fasten wooden, polyamide, and plasterboard structures to metal profile sheets.

Application - mechanical engineering, repair, internal installation work indoors, at any production facility. Due to their good technical characteristics, the scope of application of self-tapping screws is quite extensive. Self-tapping screws are widely used in many economic sectors: in various construction, repair and finishing processes, during the production, assembly and installation of furniture, installation of various hinged structures, in mechanical engineering, in everyday life, etc.

The scope of use also directly depends on the material of manufacture and the product's coating:

- Galvanized steel is a good protection against corrosion if the fastener is to be used in an aggressive environment.

- Stainless steel allows the fasteners to be used at significant temperature fluctuations and in aggressive and humid environments.