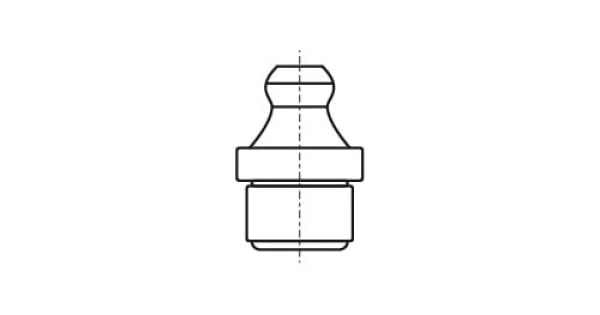

GOST 19853-74 is a standard that defines the parameters and dimensions of grease nipples used to lubricate moving parts in machinery and devices. Grease nipples are small products with a threaded end that are installed on the parts of the mechanism and allow for lubrication and lubrication change during operation. GOST 19853-74 defines the dimensions and shape of grease nipples with M6x1 and M8x1 threads. Such grease fittings are usually made of metal and have a cylinder shape with a bend at the end, which ensures ease of installation and lubrication of moving parts.

Fastening group according to GOST 19853-74

Depending on the material of manufacture, grease fittings according to GOST 19853-74 are divided into groups:

- Stainless fasteners

- High-strength fasteners

- Brass fasteners

Materials for the manufacture of GOST 19853-74 grease fittings

Grease pans of GOST 19853-74 are made of the following materials:

- Steel, which can be additionally coated with zinc. Zinc (Plated) protects against corrosion if the fastener is to be used in aggressive environments.

- Stainless steel grades A1 and A4. Stainless steel allows the fasteners to be used at significant temperature fluctuations and in aggressive and humid environments.

- Brass. Brass fasteners are used if the system is subjected to frequent dynamic, vibration and cyclic loads.

Scope of application of GOST 19853-74 grease nipples

Grease nipples in accordance with GOST 19853-74 are used in various industries and machine building, where it is necessary to ensure effective lubrication of moving parts of mechanisms. The main application of grease nipples is to ensure the operation of machinery with moving parts that require lubrication.

Here are some examples of applications for grease guns that comply with GOST 19853-74:

- Automotive industry: grease guns are used to lubricate moving parts of automotive mechanisms, such as hinges, suspensions, and other elements.

- Construction machinery industry: grease guns are used to lubricate moving parts of construction machinery, such as excavator buckets, connecting elements, etc.

- Mechanical engineering: grease guns are used to lubricate moving parts of various mechanisms, such as drives, gears, bearings, etc.

- Agriculture: grease guns are used to lubricate the moving parts of agricultural machinery such as tractors, combines, etc.

In general, grease guns in accordance with the GOST 19853-74 standard are used in any industry where it is necessary to ensure effective lubrication of moving parts of mechanisms. They help to extend the service life of equipment and reduce the risk of breakdowns and the cost of repairing them.